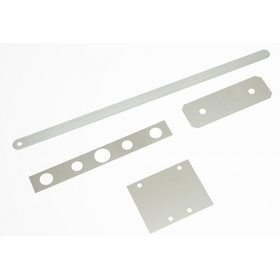

[Processing Example] Creation of a deposition mask using etching technology.

Responding to demands for flatness, magnetism, and heat resistance! Achieving a variety of small-lot projects using etching technology.

We received an inquiry regarding the creation of vapor deposition masks, and I would like to introduce it. There are projects that are trying for the first time in research institutions and prototype considerations, and they are experimenting with the characteristics of metal masks. Technically, they requested a solution without burrs and at a low cost. Additionally, there was a request based on artwork as there was no existing data. Therefore, we created a vapor deposition mask using etching technology. We are capable of responding to short lead times for prototypes and small lots, and particularly from research institutions, we have realized projects that accommodate a variety of small lots using etching technology. Furthermore, to meet product requirements for vapor deposition, we addressed demands for flatness, magnetism, and heat resistance. *For more details, please refer to the PDF document or feel free to contact us.

basic information

For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(2)

Download All CatalogsRecommended products

Distributors

Reasons to Choose P-One 1. Fastest, same-day delivery possible! 2. Capable of handling from one piece to medium production! Prototypes are also welcome! 3. Achieves low costs! 4. No original version... we can create from actual items or sketches! 5. Precise processing without burrs is possible! 【Features】 ■ We are committed to precision at the micron level ■ Proven track record in processing 5-micron thin plates ■ Bridge-less processing is also available