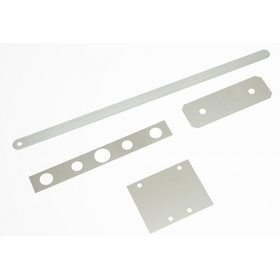

[Processing Example] Manufacturing wrapping carriers using photo etching.

Small lot support! Introduction of a case where a wrapping carrier for crystal polishing was manufactured using photo-etching.

We received a request to manufacture the wrapping carrier using photo etching that can accommodate low costs. The technical requirements specified that it should be produced without burrs and without bridges. Additionally, due to the characteristics of the product, it will not be mass-produced but rather produced in small to medium lots, with various sizes, materials, thicknesses, and warping, along with detailed requests. Therefore, we manufactured a prototype of the wrapping carrier. Since the customer requested a short delivery time, we responded with the fastest possible delivery for the prototype as well. Furthermore, we are progressing with the manufacturing while considering the process to enable handling of thin plate thickness without bridges. Depending on the material, it is also important to work quickly to prevent rust, so we are consciously paying attention to warping of the material and working diligently. *For more details, please refer to the PDF document or feel free to contact us.

basic information

For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(2)

Download All CatalogsRecommended products

Distributors

Reasons to Choose P-One 1. Fastest, same-day delivery possible! 2. Capable of handling from one piece to medium production! Prototypes are also welcome! 3. Achieves low costs! 4. No original version... we can create from actual items or sketches! 5. Precise processing without burrs is possible! 【Features】 ■ We are committed to precision at the micron level ■ Proven track record in processing 5-micron thin plates ■ Bridge-less processing is also available