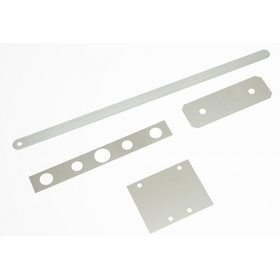

Spacer for photolithography processing for semiconductor masks.

Precision machining without burrs! We solve challenges in mask manufacturing.

In the semiconductor industry, masks are a crucial element that affects the precision of microfabrication. The quality of the mask is directly linked to the performance of semiconductor devices, requiring high precision and reliability. If the accuracy of the spacers is low, it can lead to misalignment and distortion of the mask, potentially resulting in decreased yield. Our company provides precision spacers without burrs using photolithography processing technology, contributing to solving challenges in mask manufacturing. 【Usage Scenarios】 - Semiconductor mask manufacturing - Microfabrication processes - Situations requiring high-precision spacers 【Benefits of Implementation】 - Improvement in mask quality - Enhancement of yield - Reduction in manufacturing costs

basic information

【Features】 - Cost-effective etching processing - Supports burrs, non-bridging, and small lots - Addresses diverse challenges such as size, material, and thickness - Precision at the micron level - Proven processing for 5-micron thin sheets 【Our Strengths】 - Same-day delivery at the shortest time - Supports from single items to medium production - Achieves low costs - Can accommodate without original plates - Precise processing without burrs

Price range

Delivery Time

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

catalog(1)

Download All CatalogsRecommended products

Distributors

Reasons to Choose P-One 1. Fastest, same-day delivery possible! 2. Capable of handling from one piece to medium production! Prototypes are also welcome! 3. Achieves low costs! 4. No original version... we can create from actual items or sketches! 5. Precise processing without burrs is possible! 【Features】 ■ We are committed to precision at the micron level ■ Proven track record in processing 5-micron thin plates ■ Bridge-less processing is also available