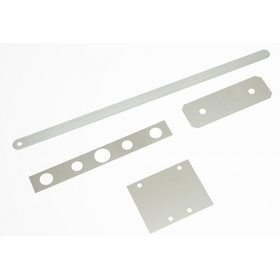

Photo-etched spacers for medical devices

Solving challenges for precision parts in medical devices! Etching processing without burrs, accommodating small lots and a variety of products.

In the medical device industry, the miniaturization and precision of products are advancing, and the quality of components is being emphasized. In particular, for precision parts such as spacers, accurate processing without burrs or distortions is required. Improper processing can lead to a decline in equipment performance or failure. Our photo-etching processing achieves precise machining without burrs, contributing to the improvement of medical device quality. 【Application Scenarios】 - Assembly of medical devices - Fixing precision parts - Adjusting fine gaps 【Effects of Implementation】 - Provision of precision parts without burrs - Support for small lots and diverse varieties - Improvement of medical device quality

basic information

【Features】 - Low-cost etching processing - Burr-free, non-bridge, small lot - Supports various sizes and challenges related to materials and thickness - Precision at the micron level - Proven processing of 5-micron thin plates 【Our Strengths】 - Shortest possible delivery, same-day delivery available - Capable of handling from single units to medium production - Achieves low costs - Can accommodate even without original plates - Capable of precise processing without burrs

Price range

Delivery Time

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

catalog(1)

Download All CatalogsRecommended products

Distributors

Reasons to Choose P-One 1. Fastest, same-day delivery possible! 2. Capable of handling from one piece to medium production! Prototypes are also welcome! 3. Achieves low costs! 4. No original version... we can create from actual items or sketches! 5. Precise processing without burrs is possible! 【Features】 ■ We are committed to precision at the micron level ■ Proven track record in processing 5-micron thin plates ■ Bridge-less processing is also available