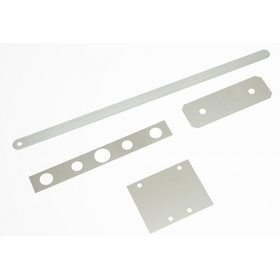

Spacer made by photo-etching process for electronic devices.

Solving challenges in circuit board design! Precision machining without burrs, accommodating small lots and a variety of products.

In the electronics industry, as the miniaturization and high density of circuit boards progress, the precision of spacers affects the reliability of products. In particular, the accurate dimensions and quality of spacers are crucial for ensuring clearance between components and for thermal management. If there are burrs or distortions, it can hinder the assembly of the circuit board and potentially lead to a decline in product performance. Our spacers, produced through photo-etching processing, address these challenges. 【Application Scenarios】 - Spacers for electronic device circuit boards - Components for precision instruments - Addressing challenges related to various sizes, materials, and thicknesses 【Benefits of Implementation】 - Providing precise spacers without burrs - Responding to needs for small lots and various types - Enabling production at low costs

basic information

【Features】 - Processing method compatible with low costs, etching processing - No burrs, non-bridge, small lots - Supports a variety of sizes and challenges such as materials and thickness - Capable of processing thin plate thickness without bridging - Depending on the material, work can be done quickly to prevent rust 【Our Strengths】 - Fastest, same-day delivery possible! - Capable of handling from one piece to medium production! Prototypes are also welcome! - Achieves low costs! - No original version... we can create from actual items or sketches! - Precise processing without burrs is possible!

Price range

Delivery Time

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

catalog(1)

Download All CatalogsRecommended products

Distributors

Reasons to Choose P-One 1. Fastest, same-day delivery possible! 2. Capable of handling from one piece to medium production! Prototypes are also welcome! 3. Achieves low costs! 4. No original version... we can create from actual items or sketches! 5. Precise processing without burrs is possible! 【Features】 ■ We are committed to precision at the micron level ■ Proven track record in processing 5-micron thin plates ■ Bridge-less processing is also available