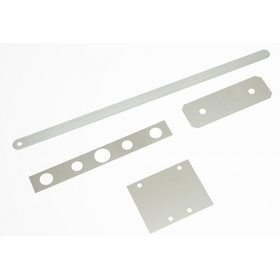

Spacer for photo-etching processing for energy storage

Photo-etching processing of precision spacers to optimize the performance of energy storage devices.

In the energy storage industry, miniaturization and high performance of devices are progressing, making internal space management crucial. In particular, spacers that accurately maintain the distance between electrodes significantly affect the efficiency and safety of energy storage devices. There is a demand for precise spacers without burrs or bridges, and material selection and cost are also important challenges. Our photochemical etching process addresses these challenges and contributes to the performance enhancement of energy storage devices. 【Application Scenarios】 - Lithium-ion batteries - Capacitors - Fuel cells 【Benefits of Implementation】 - Improved device performance - Enhanced product reliability - Cost reduction

basic information

【Features】 - Precision machining without burrs - Low-cost solutions - Support for various sizes - Capable of addressing various challenges such as materials and thickness 【Our Strengths】 - Same-day delivery at the shortest time - Support from single units to medium production - Precision at the micron level - Capable of handling without original templates

Price range

Delivery Time

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

catalog(1)

Download All CatalogsRecommended products

Distributors

Reasons to Choose P-One 1. Fastest, same-day delivery possible! 2. Capable of handling from one piece to medium production! Prototypes are also welcome! 3. Achieves low costs! 4. No original version... we can create from actual items or sketches! 5. Precise processing without burrs is possible! 【Features】 ■ We are committed to precision at the micron level ■ Proven track record in processing 5-micron thin plates ■ Bridge-less processing is also available