【事例】プラスチック粉塵による歩留まりの抑制や作業環境の改善へ!

換気を十分に取ることのできない環境においても安心!

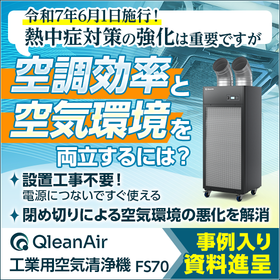

プラスチックは静電気を帯びやすいため、製造、組み立て、搬送など、様々な場面において、空気中に浮遊しているホコリやゴミを引き寄せてしまいます。 プラスチックにホコリが付着したまま組立工程に入ると「異物混入」となり、不良品が生まれる原因となります。 また、プラスチック粉塵の吸入ばく露は、人体に大きな健康被害を与えます。 『FS70』は、設置の工事は不要、可動式で、毎時3000立法メートルの処理風量をコミットします。空気中のプラスチック粉塵やホコリを含む空気を強力に吸い込み、フィルターでろ過したのち、清浄された空気を指定のエリアに確実に届けます。歩留まり率の低減、および作業員の健康被害を抑止することに貢献します。 換気を十分に取ることのできない環境においてはより効果を発揮することが見込まれます。 ぜひご検討ください。

基本情報

製品サイズ:W692xD580xH1652mm+(400mmダクト分) 消費電力:約740W(3畳用のホットカーペットと同じ) 稼働音:58db(走行中のガソリン車の車内と同じくらい)

価格帯

納期

用途/実績例

合成樹脂製品の製造、組立、搬送 ラベル貼付 準工業地帯に位置する中小規模の工場 外排気が困難な工場

カタログ(3)

カタログをまとめてダウンロードおすすめ製品

取り扱い会社

クリーンエア・スカンジナビアは、北欧発の空気環境ソリューションブランドとして30年以上の歴史を持ち、世界各国の産業・商業施設で高い評価を得ています。 快適で安全な作業環境づくりを追求し、工事不要で導入できる工業用空気清浄機を中心に、飲食店やホテル向けの脱煙機能付き喫煙ブースなど多彩な製品を展開。 独自の省エネ技術と高性能フィルターにより、粉じんやオイルミスト、浮遊菌、臭気を効率的に除去し、環境負荷を軽減しながら空気環境を最適化します。 豊富な実績と経験に裏打ちされた技術力で、お客様のニーズに応じた最適なソリューションを提供し、持続可能な環境づくりを支援しています。 また、常に最新の法規制や環境基準に対応した製品開発を行い、安全性と環境性能の両立を図っています。 お客様との密なコミュニケーションを重視し、導入からメンテナンスまで一貫したサービス体制を整備。 これにより、長期的な信頼関係を築き、業界内でのリーダーシップを確立しています。 今後も環境技術の革新を追求し、より良い空気環境の実現に貢献します。