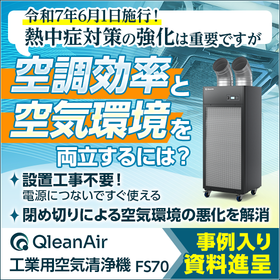

Removal of floating dust and contamination measures. Air purifier for manufacturing sites that requires no construction.

Good news for companies seeking solutions to foreign matter contamination, reduced yield, mold, and odor caused by dust generated in manufacturing sites. [*Free case study collection available*]

Dust generated in manufacturing sites causes various problems, such as reduced yield rates due to foreign matter contamination, negative impacts on worker health, and the occurrence of mold and unpleasant odors. Therefore, appropriate measures are essential. 【Do you have any of these concerns?】 ◆ I want to improve product yield affected by dust generated from processes like polishing and blasting. ◆ I want to improve the environment of workstations and site offices located near areas where dust easily flows in. ◆ I want to ventilate while maintaining indoor air quality and humidity. ◆ I am considering an environment close to a clean room but want to keep costs as low as possible. Our 'FS70' is an air purifier designed for manufacturing sites that can capture dust particles smaller than 25μm, effectively collecting even invisible airborne dust with long residence times through internal air circulation. No installation work is required, and it can be used immediately. It maintains an airflow rate of 3,000m3 per hour, covering an area the size of a tennis court with just one 'FS70' unit! Maintenance, including filter replacement, is responsibly handled by the manufacturer. *In our case studies, we widely introduce the benefits of improved yield rates, enhanced working environments, and mold suppression. Please take a look.

basic information

【Applications】 ■ Areas with insufficient ventilation, places troubled by mold and odors ■ Manufacturing industries, logistics warehouses, film factories, food factories, quasi-drug factories, printing factories ■ Areas requiring temperature and humidity control, such as refrigerated and frozen warehouses ■ Places troubled by dust generated from polishing or blasting ■ Areas where dust swirls when handling powders, feeding equipment, packaging, and weighing ■ Locations requiring clean air locally, such as in plastic and film manufacturing ■ Issues caused by dust and dirt, including equipment failures, contamination and accumulation in products, mold growth within buildings, employee health concerns, and odor management ■ Improvement of product yield 【Features】 ■ Collects invisible, long-residence-time airborne dust particles of 25μm or smaller throughout the entire area, which are difficult to capture with local exhaust dust collection devices ■ Rental contracts with maintenance service included (36 months and up) ■ Suggestions for filter combinations tailored to specific applications ■ Usable in clean rooms (with proven installations up to Class 10000) ■ Can be used in conjunction with existing dust collection devices and ventilation systems * We are currently offering a free collection of case studies that illustrate usage scenarios! Please download the PDF to view. For detailed specifications, feel free to consult us.

Price range

Delivery Time

Applications/Examples of results

Case Studies (Excerpt) ◆Reduction of dust generated during shot blasting, grinding, and cutting processes ◆Improvement of yield due to dust adhesion during film processing ◆Improvement of the working environment in factories where fine dust such as irritants and cellulose is present ◆Realization of ventilation while maintaining a constant temperature and removal of indoor dust *We are currently offering a free collection of case studies that illustrate usage scenarios! Please download the PDF to view it. For detailed specifications, feel free to consult us.

catalog(5)

Download All CatalogsRecommended products

Distributors

Clean Air Scandinavia has over 30 years of history as a Nordic air environment solution brand, receiving high acclaim in various industries and commercial facilities worldwide. We pursue the creation of comfortable and safe working environments, offering a diverse range of products centered around industrial air purifiers that can be installed without construction, including smoke-free smoking booths for restaurants and hotels. Our unique energy-saving technology and high-performance filters efficiently remove dust, oil mist, airborne bacteria, and odors, optimizing air quality while reducing environmental impact. With a wealth of proven experience and technical expertise, we provide optimal solutions tailored to our customers' needs, supporting the creation of sustainable environments. We also continuously develop products that comply with the latest regulations and environmental standards, striving to balance safety and environmental performance. We emphasize close communication with our customers and have established a consistent service system from installation to maintenance. This approach builds long-term trust and establishes our leadership within the industry. We will continue to pursue innovation in environmental technology and contribute to achieving better air environments.