news list

1~7 item / All 7 items

-

Happy New Year!

Happy New Year. Thank you very much for your support over the past year. This year, we will continue to propose and provide valuable products to protect your equipment and facilities from damage caused by explosions and overpressure. We look forward to your continued support and goodwill this year as well.

-

Measures for the prevention of hydrogen explosions.

In the international community, as the utilization of hydrogen energy, a decarbonized fuel, accelerates, initiatives are beginning to use hydrogen energy for thermal applications and as a chemical raw material. We have created a white paper on the challenges of infrastructure and safety measures for the utilization of hydrogen. Please see the related links.

-

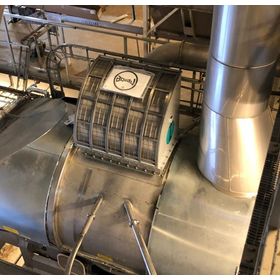

Introduction of explosion protection cases in spray dryers (spray drying equipment).

The Q-Bic explosion suppression device, developed for applications with strict hygiene requirements, is made in Germany and is compatible with spray dryers, cyclones, conveyors, bucket elevators, and more. Before an explosion occurs, the sensors of the detector detect flames or pressure and inject a highly effective extinguishing agent within a few milliseconds to contain the explosion. This time, we are introducing examples of its use in spray dryers and cyclones. Please see the related links.

-

Explosion protection in the coal handling sector

In coal processing plants such as those in power generation and the cement industry, where crushers, classifiers, filter devices, and fine coal silos are used, the risk of explosion is significantly heightened. At REMBE, we offer frameless pressure relief devices that do not require vent ducts and fully enclosed explosion venting systems that contain explosions, tailored to meet our customers' needs. All products are made in Germany and boast cutting-edge protection concepts. For more details, please see the related links.

-

Precise burst control of the rupture disk

Under the harsh conditions of the chemical industry, rupture discs perform precise burst control. They are produced in Germany using REMBE's latest processing technologies, CPL (Contour Precision Laser Processing) and CPP (Contour Precision Profiling). For more details, please refer to the related links.

-

YouTube video about rupture discs for FPSO use.

A new Japanese video has been released on REMBE's YouTube channel. This video introduces the features of rupture discs for FPSOs. Pressure relief devices play a crucial role in the production stages of oil and gas. Rupture discs are widely used in many FPSO applications due to their ability to open quickly across the entire cross-section, precise and reliable burst control, and compatibility with other pressure relief products such as safety valves. REMBE specializes in designing and manufacturing customized rupture discs for special applications like FPSOs. This not only alleviates traditional concerns in the industry but also contributes to improved safety and overall operational efficiency. REMBE is the professional that protects FPSOs! https://www.rembe.jp/applications/pressure-relief-for/fpso/

-

REMBE Safety Days - Digital Home Edition

In today's era, safety is essential. To further promote the exchange of information and interaction regarding safety concepts, we will hold the REMBE Safety Days - Digital Home Edition. This webinar is aimed at engineers, planners, operators, technicians, maintenance and safety inspectors, technical experts, and inspectors. The seminar will be held in English and is free of charge. You can register by emailing safetydays@rembe.de or by using the form at the link below. Feel free to download the current schedule from the link below.