Adhesive for fiber assembly

Acquired low outgassing standards, 85℃ 85% RH resistance, No.1 share in ferrule assembly. Products with high Tg at low temperatures and short durations, excellent workability.

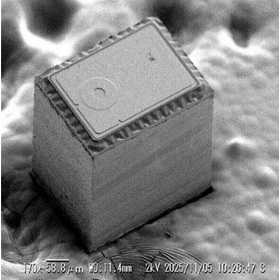

Optical communication, laser, products for glass/plastic fibers ◆ Heat-curing adhesive EPO-TEK 353ND Obtained NASA low outgassing standard (NASA ASTM E595) Outgassing below 0.1% under Telcordia(r) GR-1221 conditions Excellent high temperature and high humidity (85℃ 85% RH) and temperature cycling resistance High adhesion strength, usable with minimal application ◆ Low temperature/short time, high Tg EPO-TEK OE184 Short curing derivative of 353ND Usable at 80℃ for 25 minutes to 150℃ for 1 minute High Tg product at low temperature/short time curing Outgassing below 0.1% under Telcordia(r) GR-1221 conditions * In addition to adhesive sales, Rikei can consistently propose everything from fiber customization to termination processing, arraying, bundling, and high-power connector assembly. Please feel free to contact us if you have any issues related to optical fibers.

basic information

【353ND】 Recommended curing conditions: 150℃/1hr Other curing temperatures: 80℃~150℃ Viscosity: 3,000~5,000 cps Tg: above 90℃ 【OE184】 Recommended curing conditions: 150℃/1hr Other curing temperatures: 80℃~150℃ (short-term curing possible) Viscosity: 3,000~4,000 cps Tg: above 100℃

Price range

Delivery Time

Applications/Examples of results

Fiber assembly (ferrule assembly), connectorization, etc., optical communication.

catalog(2)

Download All CatalogsRecommended products

Distributors

Rikei Corporation was established in 1957 and is a solution vendor in the IT and electronics industry, celebrating its 65th anniversary. We propose a variety of solutions centered around cutting-edge technologies and advanced products in the fields of system solutions, network solutions, and electronic components and devices, tailored as the optimal "step-ahead solution" to meet our customers' needs.