[Magnet Installation Case] Confectionery Manufacturing Line Equipment Manufacturer

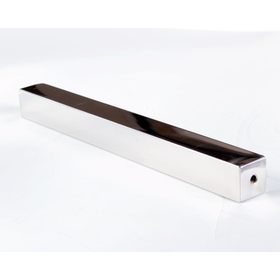

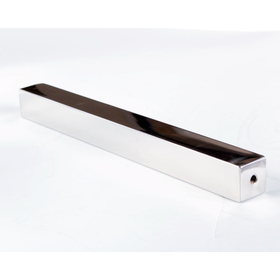

An example of installing a "single-stage magnet for rectangular hoppers" for food specifications (food-grade welding).

We were requested to install a hopper magnet for metal foreign object removal at the hopper section where raw materials are fed in, but we were having trouble finding a supplier for the magnet. The company that was introduced to us by the domestic rice cracker manufacturer was ours. We were contacted and installed a "square hopper magnet, single type" that meets food specifications (food-grade welding) at the raw material inlet. As a result, the confectionery manufacturer was very pleased. Subsequently, it was decided to transport the raw materials to the inlet via a conveyor, and we also installed a "square hopper magnet" at the previous inlet. If you are having trouble selecting a magnet to install on your production line, please consult Sangyo Supply first. 【Installation Example】 ■ Client: Confectionery manufacturing line equipment manufacturer ■ Products Installed - Square hopper magnet, single type - Square hopper magnet *For more details, please refer to the related links or feel free to contact us.

basic information

【Installation Example】 ■Issue - Requested to install a magnet for a hopper to remove metal foreign objects. ■Result - The confectionery manufacturer was pleased with the outcome. *For more details, please refer to the related links or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the related links or feel free to contact us.

catalog(2)

Download All CatalogsRecommended products

Distributors

We manufacture custom-made magnets for metal foreign object removal starting from just one unit, with a rich inventory and the ability for quick shipping. ■ We respond sincerely even for small products or single unit requests. We are committed to providing honest service for small products and requests for just one unit. ■ Processing without gaps or grooves for food applications is possible. - The joint between the magnet bar and the stainless steel plate can be welded with rounded edges. - We can polish the screw heads that secure the magnet bar and eliminate grooves on the screw heads. ■ We can assist even without drawings. Having a drawing allows for quicker responses, but we can provide estimates through communication via fax or email even without one. If possible, a sketch similar to a comic would help us respond even faster. We also handle the sale of various powerful magnets from stock and can manufacture custom-made items starting from one unit.