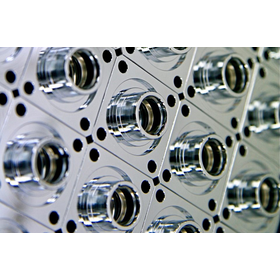

Surface treatment technology: Chrome plating

RoHS directive compliant! Decorative plating utilizing the unique beautiful white glossy appearance of chrome.

Chrome plating can be broadly classified into two types: hard chrome plating (industrial chrome plating) and decorative chrome plating. Hard chrome plating involves plating chrome in a thickness range of 5μm to 500μm, and is used in products that take advantage of its wear resistance and low friction coefficient. Our chrome plating is decorative chrome plating, which involves nickel plating as a base layer and applying chrome plating in a thickness range of 0.25μm to 1.25μm. This decorative plating utilizes the unique beautiful white luster of chrome, which is highly corrosion-resistant, hard, wear-resistant, and has excellent durability against discoloration. 【Features】 ■ Compliant with RoHS Directive ■ Difficult to wrap around weak electrical components ■ Method: Using fixtures (static plating) ■ Applicable materials: Nickel-plated products *For more details, please refer to the PDF document or feel free to contact us. 【Contact Information】 TEL: 048-994-5931 FAX: 048-994-5935 E-mail: info@silvec.co.jp

basic information

【Plating Processing Factory】 ■Yashio/Saitama: ○ Available (Can handle both hexavalent and trivalent chromium plating) ■Chonburi/Thailand: × Not available (Only trivalent chromium plating can be handled) *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

【Applications】 ■ Buff polishing and chrome plating for automotive keyless entry ZDC components ■ Chrome plating for connector shells (ADC material) for decorative and corrosion resistance purposes ■ Chrome plating for connector parts, mechanical parts, and camera parts (brass material) ■ Chrome plating for camera lens parts (aluminum material) *For more details, please refer to the PDF document or feel free to contact us.

catalog(23)

Download All Catalogs