We will prototype from a minimum of 1 piece of aluminum material.

We have a track record of various individual parts such as mirror tubes, plates, blocks, brackets, and more.

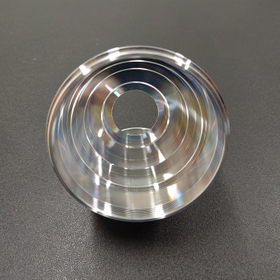

At Shinwa Koki, we handle the processing of various aluminum materials with different characteristics, ranging from the A1000 series to the A7000 series (super duralumin). Our extensive delivery track record, built up since our founding, spans a wide range of industries, from industrial machine parts to optical equipment and aerospace-related components. In particular, we have earned the trust of many customers in the processing of critical safety components that require high dimensional accuracy and geometric tolerances, as well as thin-walled shapes that are prone to deformation. We support your manufacturing with reliable technology, so that you can say, "If you have a problem with aluminum, turn to Shinwa Koki."

basic information

Corresponding materials: A1000 series (pure aluminum), A2000 series (duralumin), A5000 series (corrosion-resistant aluminum), A6000 series, A7000 series (super duralumin), cast materials, etc. Areas of expertise: Precision parts with strict geometric tolerances (flatness, perpendicularity, roundness, etc.) Processing of thin-walled and complex shapes with minimized distortion Design parts requiring high appearance quality

Price range

Delivery Time

Applications/Examples of results

Industry experience: Semiconductor manufacturing equipment, optical devices, industrial robots, aerospace, etc.

Recommended products

Distributors

Since its founding in 1979, Shinwa Koki has specialized in prototype processing. We are dedicated to passing on the skills cultivated through this prototype processing to the younger generation and are continuously striving for further advancement. Aiming to be a company that moves our customers, we will continue to face manufacturing sincerely as a united team, contributing to the local community.