"Die-cast" and "gravity" for steam oven range.

In addition to aluminum casting for the heater, there is also the option for aluminum parts to undergo pressing processing. Heating in low-temperature air, heater casting, and heater pressing are the appropriate conditions!

We would like to introduce "Die Casting and Gravity" offered by Churitsu Electric Co., Ltd. In addition to aluminum casting for sheath heaters, we also perform crimping processes on aluminum parts. We carry out aluminum casting using two methods: die casting (high-pressure casting) and gravity casting (low-pressure casting). 【Features of Die Casting】 - For heater casting, BUNDY (iron + copper plating) is used. - For heater crimping, aluminum pipes are used. - Due to die casting, the surface finish is smooth, allowing for fine machining. - It is possible to apply paint to the aluminum surface. 【Examples of Product Applications】 - Irons, hot plates, steam ovens, rice cookers, humidifiers, ice makers. *For more details, please refer to the PDF materials or feel free to contact us.

basic information

【Features of Gravity】 ■ For heater casting, BUNDY (iron + copper plating) is used ■ For heater crimping, aluminum pipes are used ■ Compared to die-casting, pinholes are less likely to occur ■ Painting on the aluminum surface is possible *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsRecommended products

Distributors

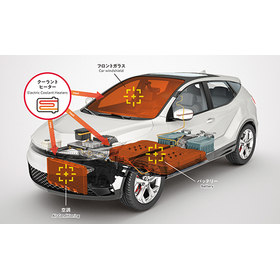

Chuo Electric Co., Ltd. provides seed heaters and component materials as the Japanese subsidiary of the SJH Group. From individual parts such as heater pipes and rubber molded products to high value-added products like assemblies and boiler units, our company not only sells ready-made products but also has the design and development capabilities to meet a wide range of specifications tailored to customer needs. Additionally, by leveraging our network of 11 locations worldwide, we are capable of supplying over 100 million products annually.