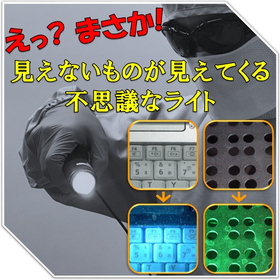

Foreign Object Detection and Leak Detection Micro-particle Visualization System

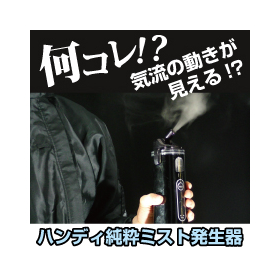

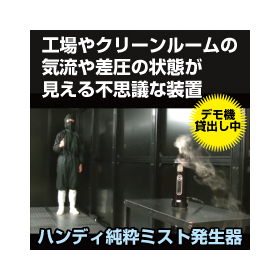

[Web demo in progress] Things that are invisible become visible! Visualizing particles and airflow in clean rooms and manufacturing equipment.

The microparticle visualization system is a system that can visualize and record invisible microparticles in real-time as images using a dedicated camera and laser illumination. It is designed not only for experimental environments but also for use at customer sites, combining the know-how gained from over 1,000 evaluation services by our technical staff, resulting in a system with unprecedented sensitivity and operability. Active in manufacturing sites for metals / plastics / resins / films / semiconductors. [For more details, please download the catalog or feel free to contact us.]

basic information

[For those with such issues] - Those who feel they are not getting closer to the cause of contamination at all - Those who are unsure if the planned local clean-up or dust collection equipment is worth the investment - Those who have tried various things but have given up thinking they are invisible - Those who want to visualize and verify the containment effect - Those who are troubled by being introduced to visualization technologies with insufficient sensitivity - Those who are struggling with insufficient sensitivity of airflow visualization devices and issues with selecting tracers - Those who want to evaluate surface foreign substances that have adhered to products as a result, rather than airborne particles - Those who are studying clean-up but are unsure if it applies to their own site - Those who find that particle counters and general analysis alone do not improve yield - Those who are not concerned about fine particles but rather want to evaluate coarse particles and dust - Those who are having difficulty resolving contamination occurring within production equipment - Those who want to visualize airflow in large spaces or server rooms - Those who want to optimize the layout of clean rooms and production equipment - Those who want to use visualization for validation in pharmaceutical processes - Those who want to visualize welding fumes, etc., to comply with specialized regulations

Price information

-

Delivery Time

Model number/Brand name

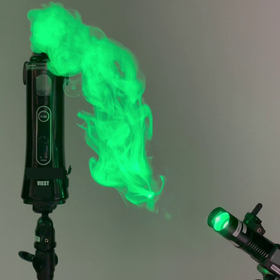

Particle Visualization System "ViEST"

Applications/Examples of results

- Identification of yield causes due to particles and airflow - Training for cleanroom operators - Evaluation of airborne contaminants in painting and coating processes - Evaluation of surface-adhered contaminants - Dust generation from moving parts and countermeasures - Airflow simulation during validation - Evaluation of airborne contaminants in filling processes for chemicals, etc. - Evaluation of dust and mist within the factory - Visualization of airflow in the furnace chamber - Evaluation of air purification equipment - Evaluation of cleaning equipment such as vacuum cleaners - Evaluation of products that generate less dust - Cooperation in filming for various media (TV, product catalogs)

Related Videos

catalog(1)

Download All CatalogsNews about this product(1)

Recommended products

Distributors

ViEST is a brand that offers unique visualization technologies, including an unparalleled ultra-high-sensitivity "fine particle visualization system," through products and services. In terms of addressing foreign substances and airflow in manufacturing environments, we provide fine particle visualization systems and contract evaluation services by specialized visualization technical staff, boasting over 3,000 successful implementations across various industries. We can strongly promote improvements in production efficiency, yield, quality control, and solutions to clean-up challenges. If you have specific targets that require measures, please feel free to consult with us. Please also take a look at our website, which provides a detailed introduction to ViEST. ⇒https://www.snk.co.jp/viest