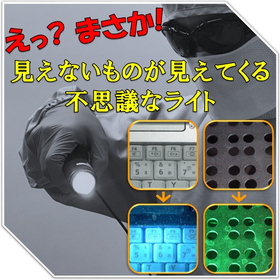

Surface observation tool "D-Light" for detecting foreign objects, dirt, and scratches.

Visualize surface foreign substances, dirt, and scratches! It is well-received as a daily management tool for yield management, quality control, cleaning management, and hygiene management. *Demo units available for loan.

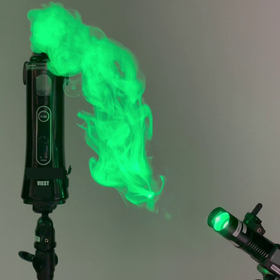

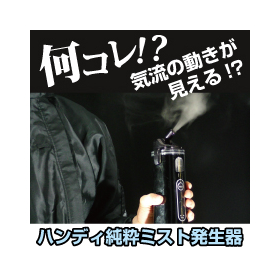

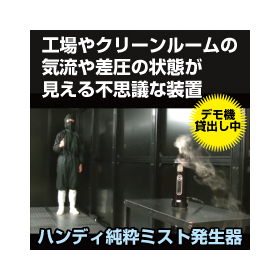

This is a tool that helps improve the efficiency of visual surface inspections. We have prepared two types. ■ D-Light Type-F The popular "D-Light" detection tool for contaminants has undergone a full model change. It has achieved higher output, compactness, lightweight design, and lower power consumption. The detection capability and portability have been further enhanced. Since the contaminants themselves emit light, they can be clearly detected visually. Additionally, by observing the differences in the emitted light colors, it is possible to estimate the types of contaminants. This is a type of surface foreign matter detection tool that has not existed before. ■ D-Light Type-P This tool is suitable for observing surface conditions, such as detecting surface scratches and adhering particles, as well as checking patterns for polishing and decoration. There has been a challenge in observing metallic surfaces, such as those on cars, due to glare caused by diffuse reflection from the surface. This product can reduce the impact of such glare, allowing for the visibility of foreign matter and other elements. It can also be used for observing powder particles and oil mist. =================== We have demo units available for loan. Please feel free to apply from our company website. ⇒ https://www.snk.co.jp/viest/

basic information

■Weight: 181 [g] ■Dimensions: W139 × D22 × H33 [mm] ■Light Color: D-Light Type-F: Violet D-Light Type-P: Green ■Usage Scenarios: Stationary: Can be installed inside equipment or on a desk for long continuous illumination Portable: Can be used without a power cord (up to 4 hours; please consult us if longer usage is needed) ■Applications: By combining with our product 'D-Scope', it enables photography, recording, and particle analysis.

Price range

P3

Delivery Time

P4

If the item is in stock, we will deliver it within two weeks after your order. Please feel free to contact us regarding the availability of stock through our company website or other means.

Model number/Brand name

ViEST

Applications/Examples of results

We are adopting it in various situations that require regular cleanliness management. - Yield management on production lines - Quality control such as pre-shipment inspections - Cleanliness checks after cleaning - Quality and hygiene management related to food, biotechnology, and pharmaceuticals - Cleaning management of medical instruments and tools - Surface quality inspection of electronic precision devices like mobile devices, automobiles, and materials - Evaluation of the finish of surface polishing and decoration - Surfaces of metals, plastics, resins, etc. Additionally, we have a proven track record of implementation in a wide range of industries, including research and development.

Detailed information

-

Sanitary ware (before D-light irradiation)

-

Sanitary ceramics (under D-light irradiation) D-light was applied to the sanitary ceramics. The dirt shines and can be clearly seen.

-

Keyboard (before D-light irradiation)

-

Keyboard (D-Light in use) The D-Light has been applied to the keyboard. You can check for dust and dirt that has adhered to it.

-

Perforated floor panel of the clean room (before D-light irradiation)

-

Perforated floor panel in the clean room (during D-light irradiation) Due to the rough surface, normal lights cause severe diffuse reflection, making observation difficult. D-light can reduce the effects of diffuse reflection, allowing for visibility of dirt and falling dust.

-

Around the car door handle / Metallic painted surface (under light irradiation) When light is irradiated on the metallic painted surface of a car, as shown in the photo, the surface condition cannot be observed due to diffuse reflection.

-

Around the car door handle / Metallic painted surface (under D-light illumination) The influence of diffuse reflection on the metallic painted surface can be almost eliminated, allowing for the visual detection of dust that is adhering to it.

Related Videos

catalog(2)

Download All CatalogsNews about this product(1)

Recommended products

Distributors

ViEST is a brand that offers unique visualization technologies, including an unparalleled ultra-high-sensitivity "fine particle visualization system," through products and services. In terms of addressing foreign substances and airflow in manufacturing environments, we provide fine particle visualization systems and contract evaluation services by specialized visualization technical staff, boasting over 3,000 successful implementations across various industries. We can strongly promote improvements in production efficiency, yield, quality control, and solutions to clean-up challenges. If you have specific targets that require measures, please feel free to consult with us. Please also take a look at our website, which provides a detailed introduction to ViEST. ⇒https://www.snk.co.jp/viest