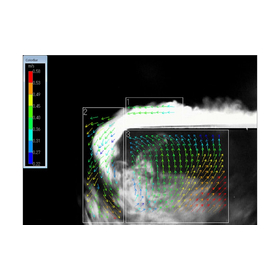

Particle Visualization System "Parallel Eye H" [Environmental Survey / Performance Evaluation]

[Web Demo in Progress] Achieve highly sensitive visualization of particles and airflow with our unique visualization system!

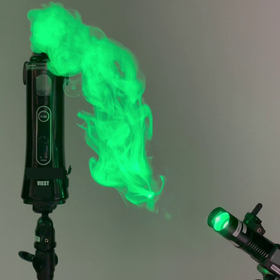

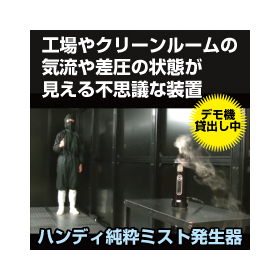

This is the high-precision model 'Type-H' of the "Particle Visualization System," which visualizes and records invisible particles in real-time as images using a combination of an ultra-sensitive camera dedicated to particle visualization, a laser light source, and image processing software. Features of 'Parallel Eye H': ■ Directivity By accurately controlling a single laser with the correct waveform, we maximize the "directivity" of the laser light to deliver light to particles that are invisible to the naked eye at a distance. ■ Control of Laser Sheet With the dial operation of the controller, precise remote control of optimal light output, spread, and irradiation angle can be achieved for each scene. ■ Usability By constructing a unique light source system, we have reduced the space required for installation, making it particularly easy to set up and handle in manufacturing environments. [For more details, please download the catalog or feel free to contact us.]

basic information

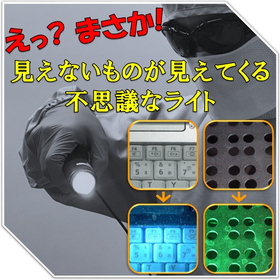

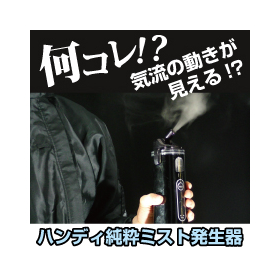

Ultra-high sensitivity camera for particle visualization "Particle Eye" Ultra-high sensitivity laser sheet light source for particle visualization "Parallel Eye H" Technical information featuring evaluation examples of particle visualization The URLs will take you to the product pages on our dedicated visualization website. Options and more We offer a variety of custom solutions that combine hardware such as light source units and cameras with software for counting, as well as various tracer generation devices for visualizing airflow, tailored to your specific applications.

Price information

Please feel free to contact us.

Delivery Time

Model number/Brand name

ViEST

Applications/Examples of results

- Identification of yield loss causes due to particles and airflow - Training for cleanroom operators - Evaluation of airborne contaminants in painting and coating processes - Evaluation of surface-adhered contaminants - Dust generation from moving parts and countermeasures - Airflow simulation during validation - Evaluation of airborne contaminants in the filling process of chemicals, etc. - Evaluation of dust and mist within the factory - Visualization of airflow in the furnace chamber - Evaluation of air purification equipment - Evaluation of cleaning equipment such as vacuum cleaners - Evaluation of products that generate less dust - Cooperation in filming for various media (television, product catalogs) Active in manufacturing sites for metals / plastics / resins / films / semiconductors

Related Videos

catalog(2)

Download All CatalogsNews about this product(1)

Recommended products

Distributors

ViEST is a brand that offers unique visualization technologies, including an unparalleled ultra-high-sensitivity "fine particle visualization system," through products and services. In terms of addressing foreign substances and airflow in manufacturing environments, we provide fine particle visualization systems and contract evaluation services by specialized visualization technical staff, boasting over 3,000 successful implementations across various industries. We can strongly promote improvements in production efficiency, yield, quality control, and solutions to clean-up challenges. If you have specific targets that require measures, please feel free to consult with us. Please also take a look at our website, which provides a detailed introduction to ViEST. ⇒https://www.snk.co.jp/viest