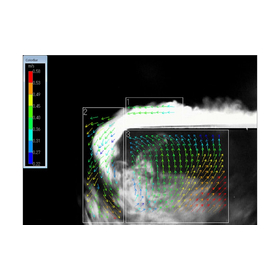

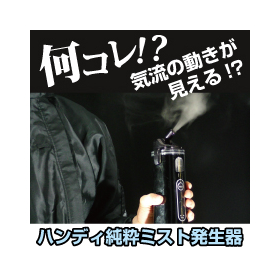

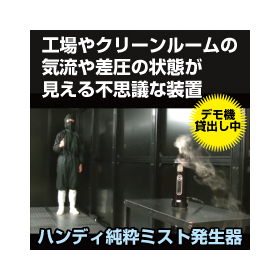

Particle Visualization System "Parallel Eye M"

[Demo units available] Floating particles in the space and adhering particles on the surface can be seen with the naked eye!

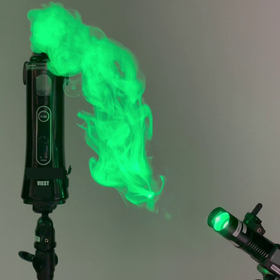

Through the optimization of the optical system, it has become a light source that reaches far with good linearity, allowing for the visualization of distant suspended particles and surface-attached particles. Additionally, it employs a highly visible green light source, enabling visual observation of particles. Despite being a non-laser light source, it allows for the high-sensitivity visualization of airflow and fine particles, and can be introduced at a relatively low cost. 【Do you have any of these concerns?】 ■ I want to check the airflow conditions in the factory or clean room... ■ I want to identify the source of suspended particles... ■ I want to visualize surface-attached particles... ● Demo units are available for free rental! Please try it out first. ● For more details, please contact us.

basic information

【For those with such challenges】 - Visualization evaluation of floating foreign substances - Visualization evaluation of surface foreign substances - Identification of yield loss causes due to particles and airflow - Feeling that we are not getting closer to the causes of foreign substance contamination - Concerned whether planned local cleaning and dust collection equipment will be worth the investment - Tried various methods but have given up thinking it’s invisible - Struggling with being introduced to visualization technologies that lack sufficient sensitivity - Studying cleanroom practices but questioning their applicability to my own site - Yield improvement is not achieved with just particle counters and general analysis - Not concerned about fine particles, but rather want to evaluate coarse particles and dust - Want to manage the manufacturing environment on a daily basis - Evaluation of cleaning equipment such as vacuum cleaners

Price information

Please feel free to contact us.

Delivery Time

Model number/Brand name

ViEST

Applications/Examples of results

- Identification of yield loss causes due to particles and airflow - Training for cleanroom operators - Evaluation of airborne contaminants in painting and coating processes - Evaluation of surface-adhered contaminants - Dust generation from moving parts and countermeasures - Airflow simulation during validation - Evaluation of airborne contaminants in filling processes for chemicals, etc. - Evaluation of dust and mist within the factory - Visualization of airflow in furnace chambers - Evaluation of air purification equipment - Evaluation of cleaning equipment such as vacuum cleaners - Evaluation of products that generate less dust - Cooperation in filming for various media (TV, product catalogs)

Related Videos

catalog(2)

Download All CatalogsNews about this product(1)

Recommended products

Distributors

ViEST is a brand that offers unique visualization technologies, including an unparalleled ultra-high-sensitivity "fine particle visualization system," through products and services. In terms of addressing foreign substances and airflow in manufacturing environments, we provide fine particle visualization systems and contract evaluation services by specialized visualization technical staff, boasting over 3,000 successful implementations across various industries. We can strongly promote improvements in production efficiency, yield, quality control, and solutions to clean-up challenges. If you have specific targets that require measures, please feel free to consult with us. Please also take a look at our website, which provides a detailed introduction to ViEST. ⇒https://www.snk.co.jp/viest