Particle Visualization System: Comprehensive Evaluation Service for Generated Particles

Evaluation of dust generation from mechanical parts and various materials. Real-time counting of the total amount of generated fine particles and particle size classification. Includes an evaluation report.

The "P-Wind" particle generation evaluation device is a new type of evaluation device developed by applying our particle visualization technology. It not only counts the total amount of particles generated from the test specimen in real-time but also simultaneously performs particle size classification. 【Features】 ■ It is capable of measuring the total amount of generated particles. Measurement and evaluation results are submitted as a report (in accordance with JIS B9926). ■ High-speed sampling technology enables highly responsive measurements. Even for test specimens with time-varying generation amounts, changes can be tracked and measured. ■ A wide range of evaluations is possible, from static products like clean supplies to dynamic products like robots. ■ Videos visualizing the particles along with count data can also be recorded, ensuring evidence of data in real-time footage. ■ The device is installed in an ISO Class 3 cleanroom, allowing measurements in an environment with almost no external influence on the data. ■ Customization of measurement conditions is also accommodated. For more details, please download the catalog or contact the person in charge.

basic information

~Fine Particle Generation Measurement Device P-Wind~ For more details, click here: https://www.snk.co.jp/viest/technology.html For inquiries, click here: https://www.snk.co.jp/info/form.html?frmid=33 Please be sure to download and view the catalog as well.

Price range

Delivery Time

Model number/Brand name

ViEST

Applications/Examples of results

■ Example of Dust Generation Evaluation - Dust generation from items brought into the clean room - Dust generation during printer operation - Dust generation associated with robot movement - Dust generation during motor operation - Dust generation during compressor operation - Dust generation associated with bearing movement - Dust generation when cutting materials etc. We are always available for inquiries regarding evaluation items and evaluable particles. Please feel free to contact us.

Detailed information

-

It is possible to quantitatively evaluate dust generation from products used in clean environments and foreign matter leakage from mechanical components of production equipment.

-

High-speed sampling technology enables highly responsive measurements. Even test specimens with time-varying generation amounts can be accurately measured for those changes.

-

We will submit a report on the results of measuring the total amount of particles generated from the test specimen.

Related Videos

catalog(1)

Download All CatalogsNews about this product(2)

-

We will exhibit a particle visualization system at the "25th International Nanotechnology Exhibition and Conference, nano tech 2026" (January 28 (Wed) - January 30 (Fri), 2026 / Tokyo Big Sight, West Hall Conference Building, West Hall 1, 1st Floor, 1W-Z34).

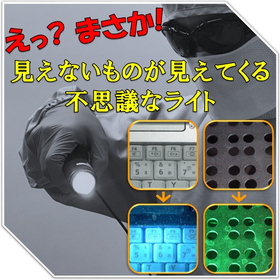

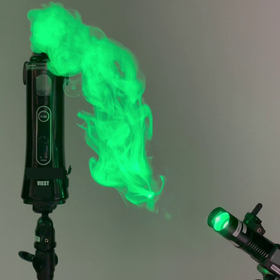

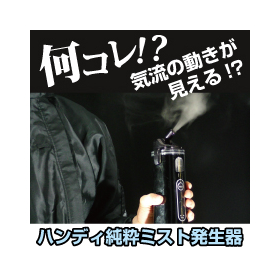

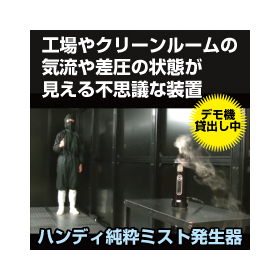

We will solve the issues related to the deterioration of defect rates caused by fine particles and the cleaning process in manufacturing sites. The fine particle visualization system developed by Shin Nippon Air Technologies, under the ViEST brand, combines an ultra-high-sensitivity camera and light source to visualize fine particles in clean rooms and equipment. It can capture their behavior in real-time while also quantifying particle information, making it a world-class visualization system. Currently, we are expanding the sale of systems and tools, as well as contract technical services utilizing them, both domestically and internationally. We have particularly rich experience in the semiconductor industry and clean rooms. Below are some examples of applications, but by using our technology, we can strongly promote solutions to various issues such as the deterioration of defect rates due to fine foreign substances, visualization of clean airflow, and concerns regarding site cleanliness. - Visualization investigation of fine particles and airflow in the manufacturing line and environmental improvement - Promotion of cleanliness in manufacturing equipment and environments - Cleanliness evaluation of various equipment performance - Improvement of yield and quality degradation caused by contamination issues - Support for research and development requiring visualization of fine particles and airflow - Evaluation of particle generation from products.

-

We will exhibit a particle visualization system at the "25th International Nanotechnology Exhibition and Conference - nano tech 2026" (January 28 (Wed) - January 30 (Fri), 2026 / Tokyo Big Sight, West Hall Conference Building, West Hall 1, 1st Floor, 1W-Z34).

We will solve the issues related to the deterioration of defect rates due to fine particles and the cleaning process in manufacturing sites. The particle visualization system developed by Shin Nippon Air Technologies, under the ViEST brand, combines an ultra-sensitive camera and light source to visualize fine particles in clean rooms and equipment. It can capture their behavior in real-time while also quantifying particle information, making it a world-class visualization system. Currently, we are expanding the sale of systems and tools, as well as contract technical services utilizing these technologies both domestically and internationally. We have particularly rich experience in the semiconductor industry and clean rooms. The following are some examples of applications, but by using our technology, we can strongly promote solutions to various issues such as the deterioration of defect rates caused by fine foreign substances, visualization of clean airflow, and concerns regarding site cleanliness. - Visualization surveys and environmental improvements of fine particles and airflow in manufacturing lines - Promotion of cleanliness in manufacturing equipment and environments - Cleanliness evaluation of various equipment performance - Improvement of yield and quality degradation caused by contamination issues - Support for research and development requiring visualization of fine particles and airflow - Evaluation of particle generation from products.

Recommended products

Distributors

ViEST is a brand that offers unique visualization technologies, including an unparalleled ultra-high-sensitivity "fine particle visualization system," through products and services. In terms of addressing foreign substances and airflow in manufacturing environments, we provide fine particle visualization systems and contract evaluation services by specialized visualization technical staff, boasting over 3,000 successful implementations across various industries. We can strongly promote improvements in production efficiency, yield, quality control, and solutions to clean-up challenges. If you have specific targets that require measures, please feel free to consult with us. Please also take a look at our website, which provides a detailed introduction to ViEST. ⇒https://www.snk.co.jp/viest