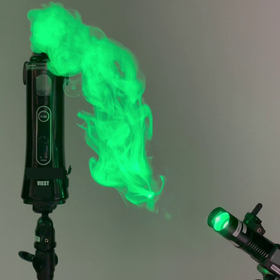

Ultra-high sensitivity particle visualization dedicated camera "Particle Eye" series

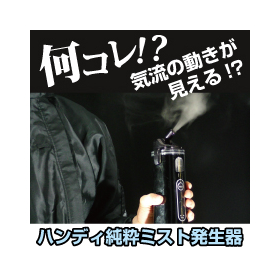

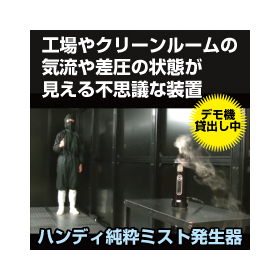

[Web demo in progress] A visualization-specific ultra-high-sensitivity camera equipped with the unique image processing technology "ViEST Engine," capable of visualizing the behavior of fine particles and airflow!

The ultra-high sensitivity particle visualization dedicated camera "Particle Eye(R)" is a digital camera specialized in detecting and quantifying weak scattered light from particles. Equipped with the uniquely developed high-speed image processing technology ViEST(R) engine, it enables high-sensitivity imaging while allowing for quantification simultaneously. While sharing ultra-high sensitivity visualization performance, you can choose from three types of lineups according to your needs: ■ Compact standard model "Particle Eye STD" ■ Model compatible with high-speed shooting "Particle Eye HS" ■ Ultra-high sensitivity model pursuing weak light sensitivity "Particle Eye EX" ■ We will exhibit at a real exhibition ■ You can experience the ultra-high sensitivity performance through demonstrations! 【 For more details, please download the catalog or contact viest@snk.co.jp 】

basic information

■ Standard model "Particle Eye STD" Dimensions: W58 × D160 × H42 [mm] (excluding lens) Maximum resolution: 1920 × 1080 Frame rate: Up to 60Hz (dependent on resolution) Reference sensitivity*: 0.2μm ■ High-speed shooting compatible model "Particle Eye HS" Dimensions: W87 × D102 × H74 [mm] (excluding lens) Maximum resolution: 1600 × 1100 Frame rate: Up to 2,500Hz (dependent on resolution) Reference sensitivity*: 0.2μm ■ Ultra-high sensitivity model "Particle Eye EX" pursuing low light sensitivity Dimensions: W103 × D152 × H105 [mm] (excluding lens) Maximum resolution: 1920 × 1920 Frame rate: Up to 120Hz (dependent on resolution) Reference sensitivity*: 0.09μm For details, please download the materials and check. *Reference sensitivity based on our unique combination with the laser light source "Parallel Eye H" when using the standard lens.

Price range

Delivery Time

Model number/Brand name

ViEST

Applications/Examples of results

- Identification of yield causes due to particles and airflow - Training for cleanroom operators - Evaluation of airborne contaminants in painting and coating processes - Evaluation of surface-adhered contaminants - Dust generation from moving parts and countermeasures - Airflow simulation during validation - Evaluation of airborne contaminants in the filling process of chemicals, etc. - Evaluation of dust and mist within the factory - Visualization of airflow in the furnace chamber - Evaluation of air purification equipment - Evaluation of cleaning equipment such as vacuum cleaners - Evaluation of products that generate less dust - Cooperation in filming for various media (TV, product catalogs)

Related Videos

catalog(1)

Download All CatalogsNews about this product(2)

-

We will exhibit a particle visualization system at the "25th International Nanotechnology Exhibition and Conference, nano tech 2026" (January 28 (Wed) - January 30 (Fri), 2026 / Tokyo Big Sight, West Hall Conference Building, West Hall 1, 1st Floor, 1W-Z34).

We will solve the issues related to the deterioration of defect rates caused by fine particles and the cleaning process in manufacturing sites. The fine particle visualization system developed by Shin Nippon Air Technologies, under the ViEST brand, combines an ultra-high-sensitivity camera and light source to visualize fine particles in clean rooms and equipment. It can capture their behavior in real-time while also quantifying particle information, making it a world-class visualization system. Currently, we are expanding the sale of systems and tools, as well as contract technical services utilizing them, both domestically and internationally. We have particularly rich experience in the semiconductor industry and clean rooms. Below are some examples of applications, but by using our technology, we can strongly promote solutions to various issues such as the deterioration of defect rates due to fine foreign substances, visualization of clean airflow, and concerns regarding site cleanliness. - Visualization investigation of fine particles and airflow in the manufacturing line and environmental improvement - Promotion of cleanliness in manufacturing equipment and environments - Cleanliness evaluation of various equipment performance - Improvement of yield and quality degradation caused by contamination issues - Support for research and development requiring visualization of fine particles and airflow - Evaluation of particle generation from products.

-

We will exhibit a particle visualization system at the "25th International Nanotechnology Exhibition and Conference - nano tech 2026" (January 28 (Wed) - January 30 (Fri), 2026 / Tokyo Big Sight, West Hall Conference Building, West Hall 1, 1st Floor, 1W-Z34).

We will solve the issues related to the deterioration of defect rates due to fine particles and the cleaning process in manufacturing sites. The particle visualization system developed by Shin Nippon Air Technologies, under the ViEST brand, combines an ultra-sensitive camera and light source to visualize fine particles in clean rooms and equipment. It can capture their behavior in real-time while also quantifying particle information, making it a world-class visualization system. Currently, we are expanding the sale of systems and tools, as well as contract technical services utilizing these technologies both domestically and internationally. We have particularly rich experience in the semiconductor industry and clean rooms. The following are some examples of applications, but by using our technology, we can strongly promote solutions to various issues such as the deterioration of defect rates caused by fine foreign substances, visualization of clean airflow, and concerns regarding site cleanliness. - Visualization surveys and environmental improvements of fine particles and airflow in manufacturing lines - Promotion of cleanliness in manufacturing equipment and environments - Cleanliness evaluation of various equipment performance - Improvement of yield and quality degradation caused by contamination issues - Support for research and development requiring visualization of fine particles and airflow - Evaluation of particle generation from products.

Recommended products

Distributors

ViEST is a brand that offers unique visualization technologies, including an unparalleled ultra-high-sensitivity "fine particle visualization system," through products and services. In terms of addressing foreign substances and airflow in manufacturing environments, we provide fine particle visualization systems and contract evaluation services by specialized visualization technical staff, boasting over 3,000 successful implementations across various industries. We can strongly promote improvements in production efficiency, yield, quality control, and solutions to clean-up challenges. If you have specific targets that require measures, please feel free to consult with us. Please also take a look at our website, which provides a detailed introduction to ViEST. ⇒https://www.snk.co.jp/viest