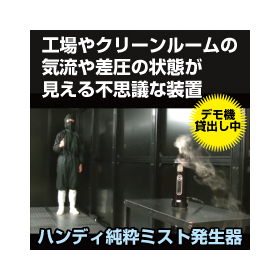

A highly experienced microparticle visualization system for solving foreign matter contamination issues.

Are you struggling with the contamination or adhesion of tiny foreign particles? Our experienced particle and airflow visualization system can help improve your yield. Please feel free to consult with us!

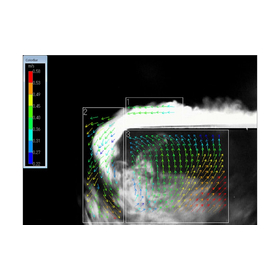

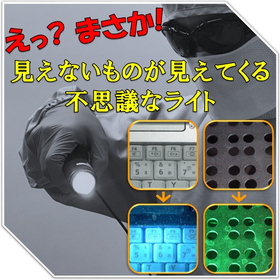

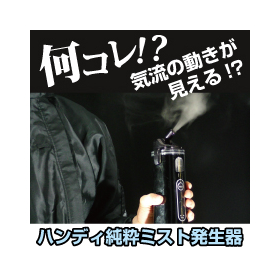

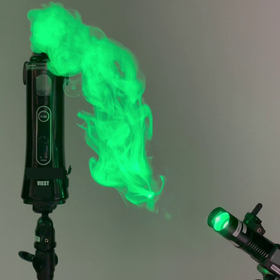

The particle visualization system has solved numerous issues related to foreign matter contamination and deterioration of cleanliness on manufacturing lines. It contributes to on-site improvements through technology and systems that visualize invisible microscopic foreign substances with high sensitivity, as well as quantitative data on the size and number of foreign matter. ■ We offer a diverse lineup of high-sensitivity systems. Cameras: Models with excellent portability, high-speed shooting compatible models, and high-spec models capable of detecting nanoparticles. Light sources: High-sensitivity, wide-range detection models, and ultra-small head models that can be used within devices. * Software is also included that allows for the acquisition of quantitative data through image processing while recording visualization footage. ■ It can be utilized in various scenes of production and quality control. ■ For more details about the system, please visit our website. Numerous shooting case videos are also available. ⇒ https://www.snk.co.jp/viest/ ■ We can introduce visualization technology in general on the web. Shooting demonstrations are also conducted. ■ You can also entrust the evaluation of the site to our specialized visualization technical staff. We often provide improvement proposals that are well received. ■ If you have any questions, please feel free to contact us through our website.

basic information

Particle Visualization Dedicated Camera Specifications ■STD Body Dimensions: W58 × D160 × H42 [mm] Maximum Resolution: 1920 × 1080 Frame Rate: Up to 60Hz (depending on resolution, etc.) Detectable Particle Size*: 0.2μm ■HS Body Dimensions: W87 × D102 × H74 [mm] Maximum Resolution: 1600 × 1100 Frame Rate: Up to 1600Hz (depending on resolution, etc.) Detectable Particle Size*: 0.2μm ■EX Body Dimensions: W103 × D152 × H105 [mm] Maximum Resolution: 1920 × 1920 Frame Rate: Up to 120Hz (depending on resolution, etc.) Detectable Particle Size*: 0.09μm *The detectable particle size is a reference value based on our proprietary standards. It may vary depending on the visualization target and usage environment. ★A light source is also necessary for visualization. Information about light sources is available on our website. ⇒ Laser light sources suitable for high-sensitivity imaging. LED light sources capable of visualizing particles that were previously difficult to detect. ★If you have any questions, please feel free to contact us. Our specialized visualization technical staff will assist you.

Price range

Delivery Time

Model number/Brand name

ViEST

Applications/Examples of results

- Identification of the causes of increased defect rates due to foreign matter contamination and consideration of solutions - Evaluation of airborne foreign matter in painting and coating processes - Dust generation from drive components and countermeasures - Evaluation of dust and mist within the factory - Visualization of airflow in furnace chambers - Evaluation of airborne foreign matter in sealed spaces such as vacuum equipment - Evaluation of airborne foreign matter in filling processes for chemicals and other substances - Consideration of airflow control measures - Airflow simulation during validation - Creation of educational materials for cleanroom workers - Evaluation of surface-adhered foreign matter - Evaluation of air purification equipment - Evaluation of splash prevention products - Evaluation of cleaning equipment such as vacuum cleaners - Evaluation of products that generate less dust - Cooperation in filming for various media (television, product catalogs) - Evaluation of dust generation levels "We can definitely assist anyone who relates to any of the following keywords: particulate matter, airflow, visualization, imaging, quantification, real-time, air pollution, surface contamination." Please feel free to consult with us. We have a proven track record of contributing to problem-solving in general manufacturing environments, specialized manufacturing environments, and cleanrooms.

Related Videos

catalog(4)

Download All CatalogsNews about this product(1)

Recommended products

Distributors

ViEST is a brand that offers unique visualization technologies, including an unparalleled ultra-high-sensitivity "fine particle visualization system," through products and services. In terms of addressing foreign substances and airflow in manufacturing environments, we provide fine particle visualization systems and contract evaluation services by specialized visualization technical staff, boasting over 3,000 successful implementations across various industries. We can strongly promote improvements in production efficiency, yield, quality control, and solutions to clean-up challenges. If you have specific targets that require measures, please feel free to consult with us. Please also take a look at our website, which provides a detailed introduction to ViEST. ⇒https://www.snk.co.jp/viest