Gas Particle Continuous Monitoring Measurement System "Particle Eye CC"

It counts particles in gas in real time while simultaneously performing particle size classification. It is a continuously monitored measurement system that can be customized according to specific purposes and applications.

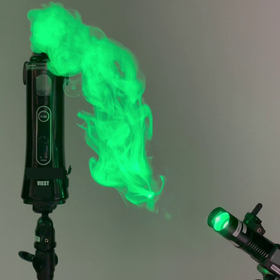

■Constant Monitoring of Particles Using Light Sheet Method■ When measuring particles in gas using a "sampling method" that involves sucking a portion of the gas into a measuring device, there are challenges with gases that are in high-temperature, high-pressure conditions, or have toxic or corrosive properties, as these gases cannot be drawn into the measuring equipment or can only be sampled for a short time. The Particle Eye CC adopts the "light sheet method," allowing for continuous imaging and simultaneous measurement of all particles passing through the light sheet with a camera, significantly reducing measurement omissions compared to the sampling method. ■Real-Time Quantification through High-Speed Image Processing■ Thanks to our uniquely developed high-speed image processing technology, the visualization of particles can be processed in real-time. Measurement processing of particles is conducted simultaneously with capturing or recording, enabling the graphing of count values and particle numbers by size, as well as visualizing the results of particle size classification. ■Customization of the System is Possible■ For example, it is possible to build a system that continuously monitors gas flowing through pipes non-contact and detects and measures particles in the gas (see "Applications and Examples" below). Experienced technicians specializing in visualization will propose a system based on discussions about your equipment situation and application needs. Please feel free to consult with us.

basic information

- Measurement frequency: 10–120Hz - Data recording interval: 0.1–60.0 sec - Maximum resolution: 800×600 - Measurement mask: Measurement range within the image can be specified as rectangle/ellipse/trapezoid - Particle size classification: 3–5 levels (separate calibration tests are required for particle size classification) - Trigger recording mode: Video recording includes a few seconds before and after when the particle count exceeds the set threshold - Scheduled measurement mode: Automatic measurement at the set measurement time from the scheduled time - Long-term continuous monitoring: Automatic data file update at date change - Monitor display: Particle monitoring video/color classification video/time series count graph/particle size classification histogram - Signal output: Signal output when the particle count exceeds the set threshold (optional) - Signal input: Recording starts triggered by signals from external sensors (optional) - Multi-camera monitoring: Monitoring measurement with up to 4 cameras (optional) *This is a reference specification using a standard camera and a computer with dedicated software installed. *The system configuration may vary depending on the application, so specifications will be discussed as needed. For customization of specifications or details about options, please feel free to contact us through our website.

Price range

Delivery Time

Model number/Brand name

ViEST

Applications/Examples of results

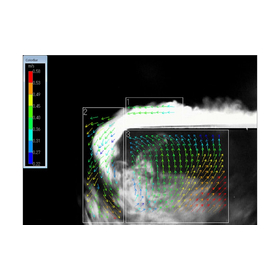

■Customization Example: Continuous Monitoring of Fine Particles in Gas Pipelines■ - System Overview Light is projected from outside the viewport into the pipeline, forming a sheet of light across the cross-section of the pipe. A camera is mounted on a viewport positioned orthogonally to the light sheet, allowing for external imaging of the pipeline (see attached image "Example in Gas Pipeline"). By adopting this light sheet method, a wide area of the pipeline cross-section can be covered, resulting in extremely low detection misses for particles during monitoring. Additionally, since this system operates in a non-contact manner where the gas and the measuring instrument do not come into direct contact, it can measure fine particles in the gas regardless of the gas's state or type. During monitoring, particle visualization images are captured simultaneously with counting and particle size classification through high-speed image processing, and the results are displayed on a computer in the form of images and graphs. (Note) While applying this to existing equipment may require modifications, our specialized technical staff can provide advice on modifications from a visualization perspective, so please feel free to consult us with confidence.

Detailed information

-

It is possible to continuously monitor fine particles in gas while simultaneously counting and classifying them by particle size.

-

The adoption of the light film method significantly reduces measurement omissions compared to the sampling method.

-

Quantitative data of count values and particle size classification results can be displayed and recorded in real-time through images and graphs.

-

- It is a system that continuously monitors and measures fine particles in the gas flowing through the piping. - Since it uses a non-contact method where the gas does not directly touch the measuring instrument, it is not affected by the state or type of gas. - The results of particle size classification from real-time measurements can be continuously displayed and recorded in both video and graph formats.

catalog(1)

Download All CatalogsRecommended products

Distributors

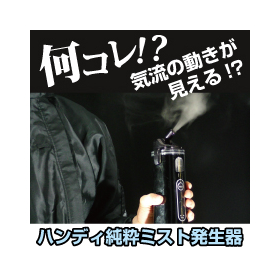

ViEST is a brand that offers unique visualization technologies, including an unparalleled ultra-high-sensitivity "fine particle visualization system," through products and services. In terms of addressing foreign substances and airflow in manufacturing environments, we provide fine particle visualization systems and contract evaluation services by specialized visualization technical staff, boasting over 3,000 successful implementations across various industries. We can strongly promote improvements in production efficiency, yield, quality control, and solutions to clean-up challenges. If you have specific targets that require measures, please feel free to consult with us. Please also take a look at our website, which provides a detailed introduction to ViEST. ⇒https://www.snk.co.jp/viest