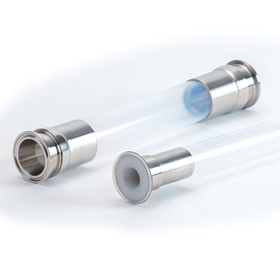

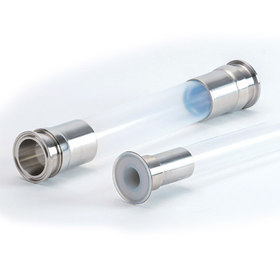

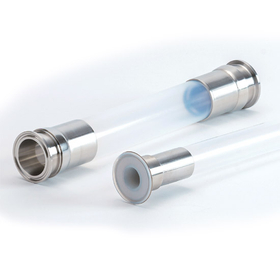

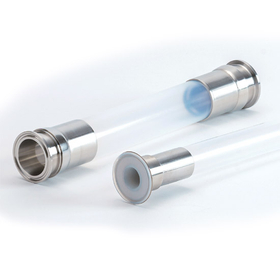

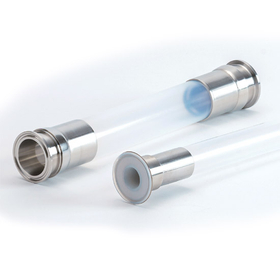

Fluororesin flow site PFA site glass for cosmetic manufacturing processes

Fluid verification in the cosmetics manufacturing process and PFA flow site designed to reduce the risk of damage.

In the cosmetics manufacturing process, properly confirming the appearance and fluid state of the contents during production leads to stable process management. The PFA resin flow sight is a product that uses a fluororesin with excellent transparency, suitable for visually confirming fluids within piping. One of its features is the expected reduction in the risk of breakage compared to glass sight glasses. 【Usage Scenarios】 - Confirmation lines before and after the filling process - Piping for raw materials and formulation processes - Piping for cleaning processes 【Benefits of Implementation】 - Improved process verification through fluid state visualization - Consideration for reducing breakage risk - Increased efficiency in maintenance and inspection tasks 【Applicable Standards】 - Food Sanitation Act

basic information

**Features** * Uses thick Teflon (PFA) tubes * Visibility + strength + lightweight * Significantly reduces the risk of damage due to resin materials * Reliable durability through dedicated fitting crimping processing * SUS exterior available as an option **Our Strengths** We have been providing various industrial products centered around industrial hoses and flexible joints. Because we have been closely engaged with the field, we are promoting company-wide development projects for products with "high safety," "high functionality," and "high efficiency."

Price range

Delivery Time

Model number/Brand name

RH10 (metal joint tightening) / RW10 (lining joint tightening) fluororesin flow site (non-glass sight gauge)

Applications/Examples of results

【Usage】 ■ Filling lines for various manufacturing processes, aseptic lines, blood/bio products, high-viscosity products, etc.

catalog(2)

Download All CatalogsRecommended products

Distributors

Our company has provided various industrial products centered around industrial hoses and flexible joints to many customers and industries. The purpose of this is none other than to enhance the important values of various equipment in the plant business: "safety," "functionality," and "efficiency." Furthermore, we are currently advancing the design, development, manufacturing, and sales of hose products and lined piping materials primarily made of Teflon (PFA/PTFE) for processes that require more precise selection of liquid contact materials. We are promoting development projects for products with "high safety," "high functionality," and "high efficiency," which is possible precisely because our company has faced and supported the field. Using the knowledge and experience we have cultivated so far, we aim to "confront more challenges, grasp essential needs, and flexibly solve problems." Under this policy, our company will continue to be a "group with will" and maintain the unwavering efforts since our founding.