【NEW】Custom Clamper AUW08 <Exhibited by M-Tech>

When air is supplied, the shaft is unclamped; when it is cut off, the shaft is clamped! Easy layout changes and connection arrangements are possible.

New product in the Quick Clamper series! Custom Clamper. When air is supplied, the shaft is unclamped, and when the air is cut off, the shaft is clamped. With the addition of linear bushes at both ends, it can withstand thrust loads. Using the custom clamper in alignment units makes it easy to change the arrangement pattern of the elements. It can be used for various applications such as height adjustment, positioning, Z-axis drop prevention, jigs, and robot hands. 【Examples of Use】 ■ Workpiece gripping ■ Height adjustment ■ Positioning ■ Z-axis drop prevention ■ Robot hand ■ Intermediate stop of cylinders ■ Fixed holding of clamp cylinders ■ Retention of chucking force ■ Drop prevention for pick & place ■ Pressure assistance for air guns *For more details, please refer to the PDF document or feel free to contact us.

basic information

What is the "Quick Clamper" series? It is a locking mechanism that allows for linear movement clamping and unclamping with a single touch, without exerting force. It enables "fixing," "safety enhancement," and "fall prevention" with stable holding power. 【Features】 ■ No force required. Easy operation with consistent holding power ■ No workpiece drop even during power outages ■ Compact design suitable for embedded applications ■ Operating guarantee of 500,000 cycles (inner unit: 100,000 cycles), with minimal wear ■ No electrical or air power needed during fixation (mechanical mechanism employed)

Price range

Delivery Time

Model number/Brand name

TPS

Applications/Examples of results

【Applications】 ■ For the adsorption, transportation, and gripping of various types of workpieces (can handle multiple workpieces with one unit due to the modular design) ■ For fixed locations that require movement (easy fixation) ■ For risk management (maintains a strong hold even during air loss or power outages) ■ For space-saving fixation (high holding power, yet compact) 【Specific Examples】 ■ Gripping workpieces ■ Height adjustment ■ Positioning ■ Z-axis drop prevention ■ Robot hands ■ Intermediate stopping of cylinders ■ Fixed holding of clamp cylinders ■ Maintaining chucking force ■ Drop prevention for pick and place ■ Pressure assistance for air guns

Detailed information

-

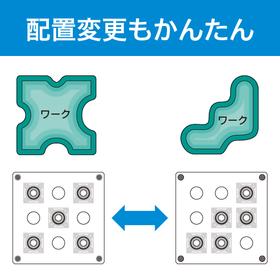

【Easy Arrangement】 By providing holes of the same diameter as the linear bush on the upper and lower base plates, simple positioning and fixation can be achieved by sandwiching them together. *It is recommended to insert rubber washers between the custom clamp and the base plate.

-

Changing the layout pattern is easy. If you set up holes in advance according to the layout pattern, you can easily rearrange them. You can build a unit that suits your purpose.

-

【Linkable Configuration】 By using link plates for a linked configuration, all connected custom clamps can be un-clamped collectively from a single supply port. (Depending on the number of linked configurations, air supply from both sides may be required.) The number of links can be changed as desired, allowing for the creation of units tailored to specific purposes. *The maximum number of links possible is 5. If you wish to link more than this, please consult our TPS division.

-

When air is supplied, it can be unclamped; when it is cut off, it can be clamped. Remote operation is possible with various control devices. It is suitable for integration into machinery.

-

【Exhibition at the 29th Mechanical Components Technology Exhibition (M-Tech)】 Date: June 19 (Wed) - 21 (Fri), 2024 Venue: Tokyo Big Sight Booth No: E20-18 (East Hall 3) You can experience the actual machines at the venue. We look forward to your visit.

-

A collection of quick clamp case studies is currently available on our website and on Ipros. You can also search for case studies by field and product specifications on our website!

Related Videos

Line up(1)

| Model number | overview |

|---|---|

| AUW08 | Custom Clamper (φ8 size) |

catalog(40)

Download All Catalogs

CAD data(63)

| Model number | overview | File |

|---|---|---|

| AUW08(2D) | Custom Clamper (φ8) |

|

| AUW08(3D) | Custom Clamper (φ8) |

|

| TCEG 08(2D) | Element (φ8, 2D) |

|

| TCEG08 (3D, no axis) | Element (φ8, 3D, no axis) |

|

| TCEG08 (3D, with axis) | Element (φ8, 3D, with axis) |

|

| TCEG 12(2D) | Element (φ12, 2D) |

|

| TCEG12 (3D, no axis) | Element (φ12, 3D, no axis) |

|

| TCEG12 (3D, with axis) | Element (φ12, 3D, with axis) |

|

| TCEG 16(2D) | Element (φ16, 2D) |

|

| TCEG16 (3D, no axis) | Element (φ16, 3D, no axis) |

|

| TCEG16 (3D, with axis) | Element (φ16, 3D, with axis) |

|

| TCEG 20(2D) | Element (φ20, 2D) |

|

| TCEG20 (3D, no axis) | Element (φ20, 3D, no axis) |

|

| TCEG20 (3D, with axis) | Element (φ20, 3D, with axis) |

|

| TCEG 25(2D) | Element (φ25, 2D) |

|

| TCEG25 (3D, no axis) | Element (φ25, 3D, no axis) |

|

| TCEG25 (3D, with axis) | Element (φ25, 3D, with axis) |

|

| TUWP 08(2D) | Plate unit (φ8, 2D) |

|

| TUWP08 (3D, no axis) | Plate unit (φ8, 3D, no axis) |

|

| TUWP08 (3D, with axis) | Plate unit (φ8, 3D, with axis) |

|

| TUWP 12A(2D) | Plate unit (φ12, 2D) |

|

| TUWP12 (3D, no axis) | Plate unit (φ12, 3D, no axis) |

|

| TUWP12 (3D, with axis) | Plate unit (φ12, 3D, with axis) |

|

| TUWP 16(2D) | Plate unit (φ16, 2D) |

|

| TUWP16 (3D, no axis) | Plate unit (φ16, 3D, no axis) |

|

| TUWP16 (3D, with axis) | Plate unit (φ16, 3D, with axis) |

|

| TUWP 20A(2D) | Plate unit (φ20, 2D) |

|

| TUWP20 (3D, no axis) | Plate unit (φ20, 3D, no axis) |

|

| TUWP20 (3D, with axis) | Plate unit (φ20, 3D, with axis) |

|

| TUWL08(2D) | Lever unit (φ8, 2D) |

|

| TUWL08(3D) | Lever unit (φ8, 3D) |

|

| TUWL16(2D) | Lever unit (φ16, 2D) |

|

| TUWL16(3D) | Lever unit (φ16, 3D) |

|

| TUSR08(2D) | Reel Clamper (φ8, 2D) |

|

| TUSR08(3D) | Reel Clamper (φ8, 3D) |

|

| TUSR12(2D) | Reel Clamper (φ12, 2D) |

|

| TUSR12(3D) | Reel Clamper (φ12, 3D) |

|

| TUSR16(2D) | Reel Clamper (φ16, 2D) |

|

| TUSR16(3D) | Reel Clamper (φ16, 3D) |

|

| TUSR20(2D) | Reel Clamper (φ20, 2D) |

|

| TUSR20(3D) | Reel Clamper (φ20, 3D) |

|

| TUSR25(2D) | Reel Clamper (φ25, 2D) |

|

| TUSR25(3D) | Reel Clamper (φ25, 3D) |

|

| TURG30B(2D) | Reel unit (φ30, 2D) |

|

| TURG30B(3D) | Reel unit (φ30, 3D) |

|

| TUWI 22C | Inner unit (φ22) |

|

| TUWI22C(3D) | Inner unit φ22 (3D) |

|

| TUSA08(2D) | Air unit 1 way (one direction) φ8 (2D) |

|

| TUSA08(3D) | Air unit 1 way (one direction) φ8 (3D) |

|

| TUSA16(2D) | Air unit 1-way (unidirectional) φ16 (2D) |

|

| TUSA16(3D) | Air unit 1-way (unidirectional) φ16 (3D) |

|

| TUWA08(2D) | Air unit 2-way (bidirectional) φ8 (2D) |

|

| TUWA08(3D) | Air unit 2-way (bidirectional) φ8 (3D) |

|

| TUWA16(2D) | Air unit 2-way (bidirectional) φ16 (2D) |

|

| TUWA16(3D) | Air unit 2-way (bidirectional) φ16 (3D) |

|

| ADLM08(2D) | Air Unit Adapter 2 (φ8, for Linear Bush, 2D) Compatible Units: TUSA08/TUWA08 |

|

| ADLM16(2D) | Air Unit Adapter 2 (φ16, for Linear Bush, 2D) Compatible Units: TUSA16/TUWA16 |

|

| ADLB08(2D) | Air Unit Adapter 1 (φ8, for LB fittings, 2D) Compatible Units: TUSA08/TUWA08 *The adapter (1) is not needed when attaching FA fittings to TUSA08/TUWA08. |

|

| ADLB16(2D) | Air Unit Adapter 1 (φ16, for LB/FA fittings, 2D) Compatible Units: TUSA16/TUWA16 |

|

| TAU-S9(3D) | Isoginchaku (Square Type with 9 Suction Pads 3D) |

|

| TAU-S9(2D) | Isoginchaku (Square Type with 9 Suction Pads 2D) |

|

| TAU-R7(3D) | Isoginchaku (Round Type with 7 Suction Pads 3D) |

|

| TAU-R7(2D) | Isoginchaku (Round Type with 7 Suction Pads 2D) |

|

News about this product(3)

-

New Edition of the Quick Clamper Comprehensive Catalog Published (TPS)

The catalog for the locking mechanism "Quick Clamper" series has been updated! It now features the newly released "Custom Clamper" along with enhanced usage examples. If you would like a printed catalog, please contact us. Additionally, we will be distributing catalogs at M-Tech Nagoya, which will be held at Port Messe Nagoya in April. ■ Custom Clamper When air is supplied, the shaft is unclamped, and when it is cut off, it clamps. (If there is residual pressure, the shaft cannot be clamped.) When used with a guiding unit, the element can adapt to the workpiece, allowing for various gripping, transporting, and supporting of workpieces with just one unit. By sandwiching two plates with holes of the same diameter as the linear bushes at both ends, simple positioning and fixation can be achieved. When connected, all Custom Clampers can be unclamped together from a single supply port. ■ 8th Nagoya Machine Elements Technology Exhibition Date: April 12 (Wed) - 14 (Fri), 2023 Venue: Nagoya International Exhibition Hall (Port Messe Nagoya) Booth No: 12-13 (New 1st Exhibition Hall)

-

New Release: Custom Clamper (TPS Quick Clamper Series)

The "Custom Clamper" has been newly released in the "Quick Clamper" series! When air is supplied, the shaft is unclamped, and when the supply is cut off, it clamps. (If there is residual pressure, the shaft cannot be clamped.) By using it with a guiding unit, the element can adapt to various workpieces, allowing for gripping, transporting, and supporting different workpieces with just one unit. By sandwiching two plates with holes of the same diameter as the linear bushes at both ends, simple positioning and fixation can be achieved. When arranged in a connected configuration, all custom clampers can be unclamped together from a single supply port. You can see the actual machine at M-Tech Nagoya, held at Port Messe Nagoya in April. ■ 8th Nagoya Machine Elements Technology Exhibition Date: April 12 (Wed) - 14 (Fri), 2023 Venue: Nagoya International Exhibition Hall (Port Messe Nagoya) Booth No: 12-13 (New 1st Exhibition Hall)

-

[Exhibition Information] 8th Nagoya Machine Element Technology Exhibition (M-Tech NAGOYA)

We will be exhibiting the revolutionary component "Quick Clamper," which changes the concept of fixation, at the "8th Nagoya Machine Elements Technology Exhibition (M-Tech NAGOYA)," where mechanical elements and processing technologies come together! We are also launching the "Custom Clamper," which unclamps the shaft when air is supplied and clamps it when the air is cut off, featuring linear bushes on both ends. We sincerely look forward to your visit! 【Exhibition Overview】 8th Nagoya Machine Elements Technology Exhibition (M-Tech NAGOYA) April 12 (Wed) - 14 (Fri), 2023 Port Messe Nagoya, Hall 12-13 (1st Exhibition Hall) 【Exhibited Products】 ● TPS "Quick Clamper" A groundbreaking component that changes the concept of fixation. It fundamentally solves issues related to fixation (positioning), such as variations in clamping force due to human strength and damage caused by over-tightening. This small component exhibits great holding power and is a labor-saving part that requires no power for fixation. It has a basic structure that ensures safety and peace of mind by always being in the direction of fixation (holding). Its applications are limitless, ranging from household items to medical and nursing supplies, as well as tools used in factories. *For details on exhibited products and demonstration machines, please refer to the catalog.

Recommended products

Distributors

Since our establishment in 1987, we have provided various FA equipment tailored to our customers' needs. Now, as a member of the THK group, the world's leading manufacturer of linear motion systems, we have 18 sales locations across Japan, responding quickly and accurately to our customers' requests.