Structure of the RIGGS series of metering pumps

Shorten the filling cycle! High-temperature products at 100°C can be used without issues such as burning!

We will introduce the structure of the air-driven piston-type metering pump "Riggs Series." It consists of the rear air pump section, the central metering cylinder section, and the head rotary valve section. To improve accuracy and reduce liquid depletion, a cut valve and nozzle are attached to the discharge end for use. The wetted parts are made of SUS316L and Teflon, and the rotor of the rotary valve is made of special stainless steel, allowing it to be used without issues even at high temperatures of 100°C without seizing. 【Features】 ■ Improved the suction and discharge single tube of the rotary valve from bolt-fixed to an integrated structure ■ Eliminates sources of contamination, allowing for thorough cleaning ■ Complies with CE (EU member country standards) and FDA (U.S. Food and Drug Administration) standards ■ Easy to finely control the forward (discharge) speed and reverse (suction) speed *For more details, please refer to the external link page or feel free to contact us.

basic information

For more details, please refer to the external link page or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please see the external link page or feel free to contact us.

Detailed information

-

Disassembly and Assembly (1) The piston head is secured with a spring clip type locking pin.

-

Disassembly and Assembly (2) Lift the spring clip and pull out the lock pin. Since it is not attached with a nut like conventional methods, it can be disassembled without tools.

-

Disassembly and Assembly (3) Remove the piston cup. The SUS plate, which consists of two pieces, along with the Teflon cup and O-ring seal, will come off as a single unit.

-

Since the entire piston cup can be completely cleaned, delicate products such as dairy products and cosmetics, which are sensitive to contamination, can be used without any contamination.

-

Disassembly and Assembly (5) It can be disassembled into the piston cup and support plate seal. When assembling, follow the reverse procedure.

Related Videos

catalog(3)

Download All CatalogsRecommended products

Distributors

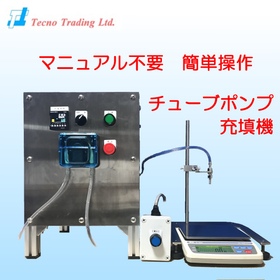

Techno Co., Ltd. offers fully automatic systems and semi-automatic filling machines that handle everything from container supply to filling, capping, labeling, and palletizing, tailored to liquids, containers, and processing capacities. We can accommodate a wide range of containers including mini bottles for cosmetics, tokkuri cans, royal cans, one-gallon cans (18L), and drum cans (180L), and we manufacture filling machines with features suitable for various high-temperature and high-viscosity liquids, as well as providing quantitative pumps and filling valves for engineers, including options for pressure-resistant and explosion-proof specifications. Please feel free to contact us regarding any inquiries about filling machines.