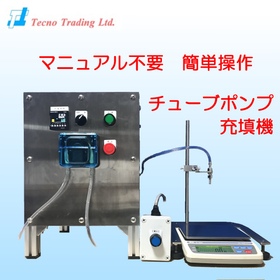

Pressure-resistant explosion-proof mobile automatic filling machine 'KANPAK EX'

The liquid connection part can be attached and detached with one touch, making product installation easy! A compact automatic filling machine.

"KANPAK EX" is a product that is primarily designed for filling hazardous materials while maintaining high operational safety and ease of use. Its footprint is very compact, roughly the size of a single pallet. It includes all the necessary functions for supplying empty cans, detecting filling openings, two-stage filling, capping, and discharging filled cans. One operator can handle everything from supplying empty cans to palletizing, making it very efficient. 【Features】 - Allows for free movement within the site, enabling direct filling from the product tank. - Utilizes a digital display load cell scale. - Easy to set various values such as required weight, upper limit, lower limit, and filling speed switching points. - Automatic drop correction function that reads the average value of the previous five cans and the set value, automatically adjusting the drop value for the sixth can. *For more details, please refer to the external link page or feel free to contact us.

basic information

【Specifications (Excerpt)】 ■ Measurement Method: Pressure-resistant explosion-proof load cell weighing and digital display ■ Filling Capacity: 4kg to 25kg ■ Filling Ability - Non-foaming products: 100 to 120 cans/hour * Depends on product viscosity, container diameter, and supply capacity - Foaming products: 50 to 70 cans/hour * Limited to long nozzle specifications ■ Filling Accuracy: ±1/500 or better ■ Filling Valve: Easy attachment, detachment, replacement, and product switching possible ■ Filling Nozzle: Short nozzle (long nozzle and nozzle insert types also available) ■ Capper: #40 or #50 crown cap * Also available as a dual-purpose machine ■ Cap Stock: 50 to 80 pieces ■ Control Device: Air-operated ■ Drive: Air-driven ■ Filling Port Detection Device: Inert gas injection device can be installed ■ Frame: Ordinary steel with painted finish, equipped with casters ■ Machine Weight: Approximately 400kg * For more details, please refer to the external link page or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the external link page or feel free to contact us.

Recommended products

Distributors

Techno Co., Ltd. offers fully automatic systems and semi-automatic filling machines that handle everything from container supply to filling, capping, labeling, and palletizing, tailored to liquids, containers, and processing capacities. We can accommodate a wide range of containers including mini bottles for cosmetics, tokkuri cans, royal cans, one-gallon cans (18L), and drum cans (180L), and we manufacture filling machines with features suitable for various high-temperature and high-viscosity liquids, as well as providing quantitative pumps and filling valves for engineers, including options for pressure-resistant and explosion-proof specifications. Please feel free to contact us regarding any inquiries about filling machines.