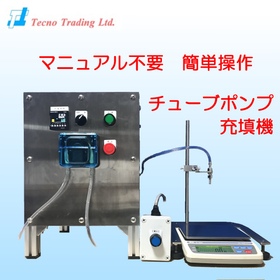

Riggs filling system

Hazardous area usable! Special stainless steel adopted, no burning even at filling temperatures close to 100℃.

This is a filling machine with a capacity that accommodates low to high viscosity liquids. By selecting the cylinder, it can fill from 10ml to 1 can or drum with single cycle filling or double-acting specified filling. It is controlled entirely by air, allowing it to be used in hazardous areas, and its simple structure ensures excellent durability. 【Features】 ■ The wetted parts are made of stainless steel (SUS 316L) ■ All-air system, suitable for use in hazardous areas ■ Easy operation! Just set the container and press the fill start button ■ Filling amount can be set using the dial counter at the rear ■ Filling accuracy: ±0.25% *For more details, please refer to the PDF document or feel free to contact us.

basic information

【Other Features】 ■ Easy disassembly and assembly of the cylinder and rotor parts ■ Easy disassembly and assembly with no hidden parts, making cleaning simple ■ Selection based on the diameter of the container and the quality of the liquid product ■ Systematized nozzles and shear blades enable efficient filling with good liquid drainage *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

【Usage】 ■ Filling of food, chemicals, paints, solvents, etc. *For more details, please refer to the PDF document or feel free to contact us.

Related Videos

catalog(3)

Download All CatalogsRecommended products

Distributors

Techno Co., Ltd. offers fully automatic systems and semi-automatic filling machines that handle everything from container supply to filling, capping, labeling, and palletizing, tailored to liquids, containers, and processing capacities. We can accommodate a wide range of containers including mini bottles for cosmetics, tokkuri cans, royal cans, one-gallon cans (18L), and drum cans (180L), and we manufacture filling machines with features suitable for various high-temperature and high-viscosity liquids, as well as providing quantitative pumps and filling valves for engineers, including options for pressure-resistant and explosion-proof specifications. Please feel free to contact us regarding any inquiries about filling machines.