Simple Cap Tightening Machine 'CAPMATE II'

Compact, precise, and economical! With a simple structure, it has fewer breakdowns and is very easy to use!

"CAPMATE II" is a compact, lightweight, and economical simple cap tightening machine. The torque can be adjusted continuously, and when the cap is tightened, the torque automatically cuts off and stops. Changing the cap chuck and insert is easy and hassle-free. By attaching a spring balancer to the main body’s hanger, work efficiency is improved. 【Features】 ■ Torque can be adjusted continuously ■ Available in low torque and high torque types ■ Can be used anywhere with AC100V (an air-operated version is also available for hazardous areas) ■ Cap tightening operation is simple ■ Low noise and low vibration *For more details, please refer to the PDF materials or feel free to contact us.

basic information

【Specifications】 ■Model: Standard Torque Specification ■Power Consumption (W): Approximately 40W ■Input Power Supply: AC100 V ±5% ■Output Torque Range: N·m (kgf·cm) 0.9–3 (9–30) ■No-load Rotational Speed (r.p.m) ±10%: 700 ■Dimensions (mm): Grip Diameter φ37.8, Total Length 280 ■Weight (g): 660 ■AC Driver Cord Length Standard: 3m Cord *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

Detailed information

-

Bracket example: Bracket with hinge for eye drop container Safe holding even for small containers.

-

Bracket example: 2-tier bracket for square containers Accommodates the shape of the container Safe for tall containers as well

-

Custom chuck made of AL with a knurled type. It is a custom chuck designed to match the shape of the cap.

-

Custom large AL-made chuck with knurling type A dedicated chuck is created to match the cap shape.

catalog(4)

Download All CatalogsRecommended products

Distributors

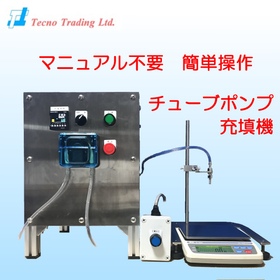

Techno Co., Ltd. offers fully automatic systems and semi-automatic filling machines that handle everything from container supply to filling, capping, labeling, and palletizing, tailored to liquids, containers, and processing capacities. We can accommodate a wide range of containers including mini bottles for cosmetics, tokkuri cans, royal cans, one-gallon cans (18L), and drum cans (180L), and we manufacture filling machines with features suitable for various high-temperature and high-viscosity liquids, as well as providing quantitative pumps and filling valves for engineers, including options for pressure-resistant and explosion-proof specifications. Please feel free to contact us regarding any inquiries about filling machines.