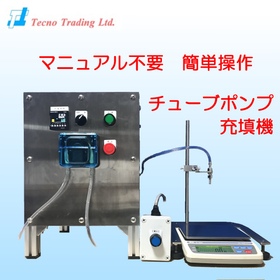

All-air control capacity filling machine

It is possible to fill solid food products up to about 25mm in size, as well as ultra-high viscosity products!

This product can fill solid food items up to approximately 25mm in size, as well as ultra-high viscosity products. Due to the small number of parts, it can be easily disassembled for cleaning. Disassembly and reassembly can be completed in about 5 minutes. 【Features】 ■ Capable of filling solid food items up to approximately 25mm in size ■ Easy to clean due to the small number of parts that can be disassembled ■ Disassembly and reassembly can be completed in about 5 minutes *For more details, please refer to the PDF document or feel free to contact us.

basic information

【Specifications (Excerpt)】 ■ Wetted Parts Material - SUS316L stainless steel, special stainless steel (rotor part) - O-rings prepared in Viton, nitrile, and Teflon according to the liquid type ■ Wetted Parts Configuration: Measuring cylinder section, rotary valve section, filling cut valve section ■ Filling Cut Valve - Air-operated standard cut valve (1.1/2” diameter), (2.0” diameter) - Blanger valve (019, 25, 30, 35mm diameter) - Shear blade (16, 22, 30mm diameter) ■ Filling Nozzle - Wetted parts made of standard SUS316L, single-hole nozzle and multi-hole nozzle of various sizes - Long nozzle for foaming products with different diameters and lengths ■ Liquid Supply Port: Heller specification joint (1.5 or 2.0 inches) ■ Filling Machine Frame: SUS304 frame or ordinary steel painted finish ■ Control/Drive - Selectable between all-air system or electric-air combined system depending on filling machine specifications - Operating air pressure: 5kg/cm2 or more, 300L/min ■ Filling Accuracy: ±1/400 or less * When filling a water-like substance with the cylinder at full stroke * For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsRecommended products

Distributors

Techno Co., Ltd. offers fully automatic systems and semi-automatic filling machines that handle everything from container supply to filling, capping, labeling, and palletizing, tailored to liquids, containers, and processing capacities. We can accommodate a wide range of containers including mini bottles for cosmetics, tokkuri cans, royal cans, one-gallon cans (18L), and drum cans (180L), and we manufacture filling machines with features suitable for various high-temperature and high-viscosity liquids, as well as providing quantitative pumps and filling valves for engineers, including options for pressure-resistant and explosion-proof specifications. Please feel free to contact us regarding any inquiries about filling machines.