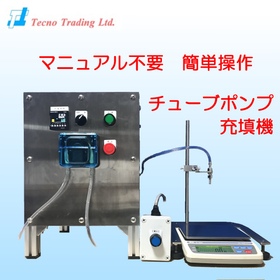

Weight management filling machine that reduces cleaning burden.

The liquid connection part consists only of a tube. A filling solution that reduces the effort of cleaning processes and product changeovers, enhancing on-site efficiency.

This device adopts a design that achieves stable filling through a weight management method while minimizing the effort required for cleaning and changeovers. Since the contact part consists only of tubes, the cleaning process during product changes can be kept to a minimum. It is suitable for small-lot production of various items such as daily necessities and cosmetics, and it performs well in environments that prioritize work efficiency. Customization options such as specification changes and additional features are also available. 【Features】 ■ Contact part has a tube structure ■ Reduces the workload during product changes ■ Simple one-touch operation for settings ■ Weight control that does not require drop correction ■ Smooth adjustment of filling quantity ■ Labor-saving preparation for work *For more details, please download the PDF or feel free to contact us.

basic information

【Main Specifications】 ■Measuring Device: Electronic Platform Scale ■Minimum Memory: 0.1g ■Filling Range: Up to 1,200g ■Discharge Flow Rate: 350 to 1,000mL/min *For more details, please download the PDF or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

Related Videos

catalog(1)

Download All CatalogsRecommended products

Distributors

Techno Co., Ltd. offers fully automatic systems and semi-automatic filling machines that handle everything from container supply to filling, capping, labeling, and palletizing, tailored to liquids, containers, and processing capacities. We can accommodate a wide range of containers including mini bottles for cosmetics, tokkuri cans, royal cans, one-gallon cans (18L), and drum cans (180L), and we manufacture filling machines with features suitable for various high-temperature and high-viscosity liquids, as well as providing quantitative pumps and filling valves for engineers, including options for pressure-resistant and explosion-proof specifications. Please feel free to contact us regarding any inquiries about filling machines.