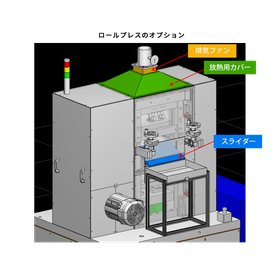

[Development Case] Strengthening Safety of Roll Press

Introducing a development case of a roll press that has enhanced safety measures by adding a slider to the material input port!

We would like to introduce a development case conducted by our company using the strip method. Unlike the winding method, the strip method requires manually pushing the material close to the roll. At this time, to prevent hands from getting caught in the roll, a safety cover is installed at the material's entry point. Normally, this specification meets safety measures, but the company we are introducing this time requested even higher safety standards. We considered whether it was possible to create a system that would eliminate the need to bring fingers close to the roll in the first place. This led to the creation of the roll press with a slider. [Case Overview] ■ Customer: Company ■ Application: Prototype of a battery ■ Request: To implement thorough safety measures to prevent hands from getting caught in the roll press *For more details, please download the PDF or feel free to contact us.

basic information

For more details, please download the PDF or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

catalog(5)

Download All CatalogsRecommended products

Distributors

Since its establishment, Sunk Metal has made remarkable progress in the Japanese industrial sector, contributing to the energy field. Over the years, we have learned from the know-how and achievements we have accumulated that the concept of "high-performance manufacturing with functionality, even if small" is essential. Since then, we have built a completely customized design, development, and manufacturing system tailored to the strict needs of users, while proposing products that can meet various standards. As globalization continues to expand, Sunk Metal, which challenges the forefront of Japan's proud processing technology, will continue to refine its skills to become a pioneering company in energy-related processing technologies, including lithium-ion batteries, which are the main players in green energy. With our "shining technology, even if small," we will continue to strive as a company that is environmentally friendly and people-friendly. We kindly ask for your continued support.