OCTレーザ溶接モニタリングシステム

溶接プロセスの品質保証のためのユニークで差別化されたソリューションを提供します!

OCTレーザ溶接モニタリングシステムは、レーザ溶接前のシームトラッキング、溶接中のキーホール計測、溶接後の欠陥・不良検査の3種類をモニタリングすることができます。また現在ご使用中のガルバノスキャナや加工ヘッドに取付けてモニタリングすることも可能です。 OCT付きレーザ加工ヘッドLSOは、加工ヘッド内の集光レンズがX/Y/Zの3軸が動く機構になっており、OCTでトラッキングした情報をクローズドループでLSOにフィードバックし、高速で精密なシームトラッキング溶接を可能にします。 また、フォトダイオードベースのレーザ溶接用モニタリング装置「WELDCHECK」や、レーザブレージング用のモニタリングモジュール「WELDEYE」など、アプリケーションに応じた各種モニタリング装置もございます。

基本情報

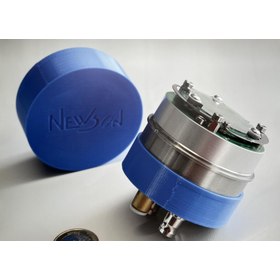

【ラインアップ】 ■OCTSCAN2.5:OCTセンサー内蔵レーザ溶接用スキャナ光学系 ■OCT250:OCTセンサー ■LSO incl. OCT250:OCTセンサー付き溶接用固定光学ヘッド(レンズシフト付)

価格帯

納期

用途/実績例

【アプリケーション例】 ● 自動車ドア溶接のシームトラッキング、溶接後の欠陥・不良検査 ● ヘアピン溶接のポジショニング、溶接後の欠陥・不良検査 ● 隅肉・突合せ・Tジョイント溶接のシームトラッキング ● 重ね合せ・隅肉・突合せ・Tジョイント溶接後の欠陥・不良検査 ● 非貫通溶接のキーホール測定 ● ギャップ計測・管理、 など