配管洗浄に!温調配管洗浄機「スカットス」

ダイカスト金型や大きな金型の温調配管・冷却管の配管洗浄が、スカットスで可能に!

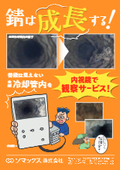

金型温調配管洗浄機『スカットス』は、従来機の『ウォーターリーマー』の機能に加え、洗浄液量が60Lに大幅にアップ。ダイカスト金型や大型金型の温調配管洗浄や、マニホールドやホッパー下にも対応できるようになりました。 また、浸透力がさらに高くなった専用洗浄液(スカットス WR-1)との相乗効果で洗浄力を最大限に引き出します。 人手不足解消にお役立て下さい。 【特長】 〇大型金型、ダイカスト金型、マニホールド、ホッパー下にも対応可能 〇流量計内蔵で洗浄効果を数値で把握 〇ポンプパワーが3倍に(WR-11-ADIII比) 〇配管径に合わせてポンプパワー出力を自動制御 〇除錆と同時に自動で防錆被膜まで形成 〇ハイブリッド洗浄で洗浄力アップ

基本情報

金型温調配管洗浄機スカットスは ・金型メンテナンスの自動化を考えておられる企業様 ・人手不足を解消したい企業様 ・成形不良を削減したい企業様 ・成形品の品質向上を図りたい企業様 ・金型温調配管のメンテナンスを簡単に実施したい企業様 以上のようなご希望をお持ちの企業様に好適な商品です。

価格情報

お問い合わせください。

納期

型番・ブランド名

金型温調配管洗浄機スカットス

用途/実績例

各種金型製造、成形を行う企業様にてご使用いただいています。 ・樹脂射出成形 ・押出成形 ・ブロー成形 ・ダイカスト成形 ・各種部品加工 など 【改善例】 ・金型を分解しないので気軽に水管のメンテナンスができる ・金型冷却水の流量が改善された ・錆や堆積物が除去され、金型冷却効率が改善された ・防錆効果のおかげで温調配管内が腐食に強くなった ・新型から使用し、予防保全で錆知らずになった ・人手不足が解消できた

関連動画

カタログ(6)

カタログをまとめてダウンロードこの製品に関するニュース(9)

-

「大阪府ものづくり優良企業賞2022」審査員特別賞を受賞いたしました

「大阪ものづくり優良企業賞2022」(大阪中小企業顕彰事業実行委員会※)において、ソマックス株式会社が「優良企業賞」ならびに「知的財産部門賞」を受賞。さらに『世界初の独自の洗浄液と洗浄液で従来の金型メンテナンスの手法に一石を投じた企業』として審査員特別賞をいただきました。 この「大阪ものづくり優良企業賞」は学識経験者等で構成する審査委員会が“技術”・“QCD”・“財務”・“CSR”の4つの視点で審査するもので、このたび優れた大阪の『匠』(大阪のものづくり看板企業)にソマックス株式会社が選定されました。 これからも日本と世界の“ものづくり”を支える“大阪のものづくり企業”として、より良いものづくりに励んでまいります。 ※大阪中小企業顕彰事業実行委員会 大阪府、大阪府商工会議所連合会 大阪府商工会連合会、公益財団法人大阪産業局、大阪産業技術研究所で構成

-

新カタログ【マンガ】夏の金型対策は「配管洗浄」で解決!を公開

新カタログ【マンガ】夏の金型対策は「配管洗浄」で解決!を公開いたしました。 このようなお悩みの皆さまにピッタリなカタログとなっております。 ●糸引き、ヒケ、反りといった成形不良率の増加 ●歩留まり率の低下 ●成形品の冷却時間の延長 ●成形サイクルの長期化 ●電気代、水道代、材料費の増加 本格的な夏到来で、成形不良率の増加や、冷却時間の延長でお困りの皆さま、ぜひご覧ください!

-

MOBIOにて常設展示がスタート

先月よりMOBIO(ものづくりビジネスセンター大阪)にて、当社の常設展示が始まりました。「ものづくり企業の総合支援拠点」であるMOBIOでは、たくさんのものづくり企業様が創意工夫された展示物がズラリ!企業様や製品などの情報収集にぜひ足をお運びください。

-

ホームページ「お役立ち情報」マンガをスタート!

ソマックス株式会社のホームページにて「お役立ち情報」ページを開始いたしました! 本ページでは、金型業界の動向や、当社製品の導入メリット、事例紹介など、様々なお役立ち情報をマンガやイラストを混じえて、分かりやすく公開しています。ぜひご覧ください!

-

オンラインで製品デモを実施中(ソマックス株式会社)

ソマックス(株)では、現在オンラインで製品のデモンストレーションを行っています。 当社スタッフが実際に製品をお見せしながら説明や操作を行います。 ご不明な点はその場で回答いたしますので、当社製品のご検討や金型メンテナンスの情報収集にお役立てください。 ※SkypeやZoomや等のオンライン会議システムを使用します。 ※英語での対応も可能です。 <対象> ●当社製品をご検討中の企業様 ●金型メンテナンスの情報収集中の企業様 ほか ●製品の勉強会も企画いたします。お気軽にご連絡ください。 <オンラインデモのご紹介> (日本語版)http://www.somax.co.jp/news/online.html (英語版) http://www.somax.co.jp/en/news/online.html ※当社サイトにジャンプします。 <ご連絡方法> イプロスまたは当社「お問合わせ」フォームよりご連絡ください。 https://ssl.alpha-mail.ne.jp/somax.co.jp/contact/request.php