【解決提案事例】ミストコレクターのメンテナンス頻度を削減!

メンテナンス周期の長期化による工数削減、加工機外へのミスト漏れの減少、工場内ミスト改善を両立!

【解決提案事例】 ■従来の方法 ・フィルター式ミストコレクターを使用 ・サイクロン式ミストコレクターを使用 ■問題点 ・ミストコレクターのメンテナンスが頻繁に必要 ・オイルミストが飛散し工場の床が滑る ■あるべき姿(理想の条件) ・オイルミストがしっかり捕集され、工場内に飛散しない ・メンテナンス周期も長く、工数がかからない ■アピステのご提案 ・メンテナンス周期の長いミストコレクター、GMEシリーズを設置 ・各加工機ごとに必要風量の再計算および現状の風量調査 ■メリット ・メンテナンス周期の長期化による工数削減 ・風量維持により加工機外へのミスト漏れの減少 +α 大幅な省エネを実現(※省エネモード搭載機種) ※詳しくは関連商品カタログをご覧いただくか、お気軽にお問合せ下さい。

基本情報

環境改善、温調・空調共に手掛けるアピステだからこそ可能な事例です。 アピステはミストコレクターだけでなく、集塵機や空調機も手掛けているため、ミスト対策や粉塵対策、機器・作業者保護を得意としております。 それぞれの現場にあった最適な改善方法をご提案させていただきますので、お気軽にお問い合わせください。 ※詳しくはPDF資料をご覧いただくか、お気軽にお問い合わせ下さい。

価格帯

納期

用途/実績例

※詳しくはPDF資料をご覧いただくか、お気軽にお問い合わせ下さい。

詳細情報

カタログ(1)

カタログをまとめてダウンロードこの製品に関するニュース(6)

-

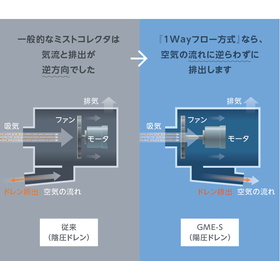

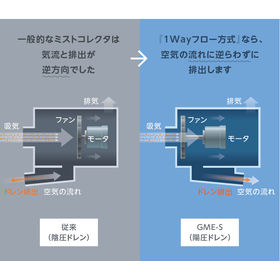

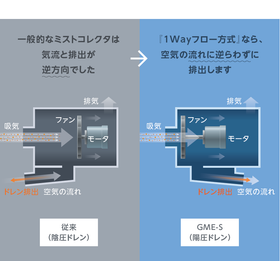

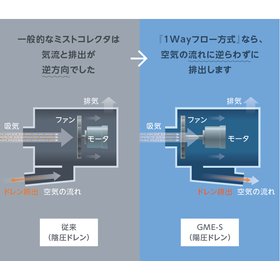

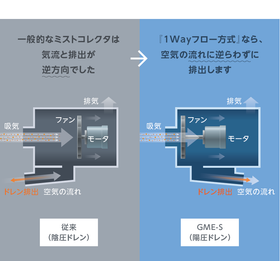

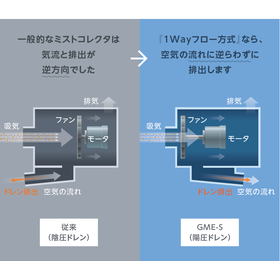

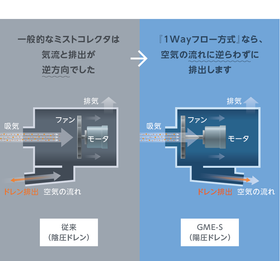

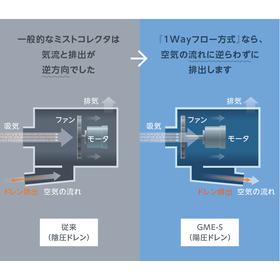

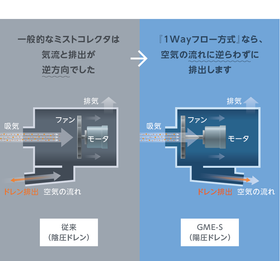

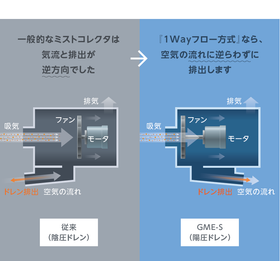

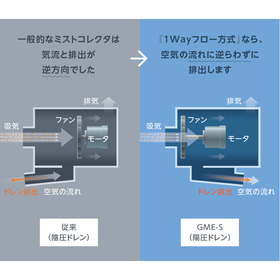

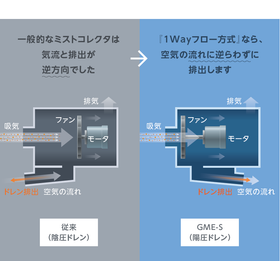

【改善事例】切子や砥粒を吸引しても内部に溜め込まない「1Wayフロー方式」のミストコレクターGME-Sシリーズカタログを公開中!

環境改善、空調・温調共に手掛けるアピステだからこそ可能な、研磨工場での事例となります。 従来はミストコレクターを設置してもフィルターがすぐに詰まってしまい、工場内にミストが蔓延していました。 【解決提案事例】 ■従来の方法 ・フィルター式ミストコレクターを使用 ■問題点 ・切子や砥粒が混ざったオイルミストを吸引することにより、ミストコレクターのフィルターがすぐ詰まる ・ミストコレクターのメンテナンスが頻繁に必要 ・オイルミストが飛散し匂いとモヤが発生 ■あるべき姿(理想の条件) ・切子や砥粒が混ざったオイルミストを吸引してもミストコレクターが詰まらない ・オイルミストがしっかり捕集され、工場内に飛散しない ・メンテナンス周期も長く、工数がかからない ■アピステのご提案 ・切子や砥粒を吸引しても内部に溜め込まない「1wayフロー方式」を採用し、メンテナンス周期の長いミストコレクターGME-Sシリーズを設置 ■メリット ・メンテナンス周期の長期化による工数削減 ・加工機外へのミスト漏れの減少による環境改善

-

【解決提案事例紹介】固形物が混ざるオイルミストも捕集し続けられるミストコレクター!内部で詰まらない秘訣は「1wayフロー方式」

環境改善、空調・温調共に手掛けるアピステだからこそご提案可能な、研磨工場での事例です。 従来はミストコレクターを設置してもすぐに詰まってしまい、工場内にミストが蔓延していました。 【解決提案事例】 ■従来の方法 ・フィルター式ミストコレクターを使用 ■問題点 ・固形物が混ざったオイルミストを吸引することにより、ミストコレクターがすぐ詰まる ・ミストコレクターのメンテナンスが頻繁に必要 ・オイルミストが飛散し匂いと靄が発生 ■あるべき姿(理想の条件) ・固形物が混ざったオイルミストを吸引してもミストコレクターが詰まらない ・オイルミストがしっかり捕集され、工場内に飛散しない ・メンテナンス周期も長く、工数がかからない ■アピステのご提案 ・固形物もスムーズに排出できる「1wayフロー方式」を採用し、メンテナンス周期の長いミストコレクターGME-Sシリーズを設置 ■メリット ・メンテナンス周期の長期化による工数削減 ・加工機外へのミスト漏れの減少による環境改善

-

【長期間交換不要】ミストがミストコレクター排気部より漏れる事象を解決する、スモークキャッチフィルターのカタログを公開中!

油の種類によっては、ミストコレクターを設置しても排気部よりミストが漏れ出ることがあり、一般的にアフターフィルターを追加して対応します。 しかし、アフターフィルターの種類によってはすぐの交換が必要です。 発生するオイルミストを処理し続けられるよう、長期間交換不要なスモークキャッチフィルターを開発しました。 【解決提案事例】 ■従来の方法 ・ミストコレクターを使用 ■問題点 ・ミストコレクター設置するも、排気部よりミスト漏れ ・フィルター装着してみたがすぐ交換が必要で費用・工数がかかる ■あるべき姿(理想の条件) ・ミストコレクター排気部よりミストが漏れない ・メンテナンス周期も長く、工数がかからない ■アピステのご提案 ・メンテナンス周期の長いミストコレクター、GMEシリーズとSCFフィルターを設置 ■メリット ・排気部からのミスト漏れが解消 ・メンテナンス周期の長期化による工数削減 ・風量維持により加工機外へのミスト漏れの減少 +α 大幅な省エネを実現(※省エネモード搭載機種)

-

【解決提案事例紹介】ミストがミストコレクター排気部より漏れる事象を解決!長期間交換不要なスモークキャッチフィルターを取付、工数を増やさず環境改善を実現!

油の種類によっては、ミストコレクターを設置しても排気部よりミストが漏れ出ることがあり、一般的にアフターフィルターを追加して対応します。 しかし、アフターフィルターの種類によってはすぐの交換等が必要です。 発生するオイルミストを処理し続けられるよう、長期間交換不要なスモークキャッチフィルターを開発しました。 【解決提案事例】 ■従来の方法 ・ミストコレクターを使用 ■問題点 ・ミストコレクター設置するも、排気部よりミスト漏れ ・フィルターを装着するとすぐに交換が必要で費用・工数がかかる ■あるべき姿(理想の条件) ・ミストコレクター排気部よりミストが漏れない ・メンテナンス周期も長く、工数がかからない ■アピステのご提案 ・メンテナンス周期の長いミストコレクター、GMEシリーズとSCFフィルターを設置 ■メリット ・排気部からのミスト漏れが解消 ・メンテナンス周期の長期化による工数削減 ・風量維持により加工機外へのミスト漏れの減少 +α 大幅な省エネを実現(※省エネモード搭載機種)

-

【解決提案事例紹介】ミストコレクターのメンテナンス頻度を減らしつつ、ミスト環境を改善!漫画6ページで簡単解説したカタログ公開中!

環境改善、空調・温調共に手掛けるアピステだからこそ可能な事例をご紹介させていただくカタログ公開中です。 せっかくミストコレクターを設置しても、メンテナンスがネックとなり本来の性能を発揮できていないともったいないですよね。 また、エアコン等の空調の汚れ・能力低下にも繋がります。 【解決提案事例】 ■従来の方法 ・フィルター式ミストコレクターを使用 ・サイクロン式ミストコレクターを使用 ■問題点 ・ミストコレクターのメンテナンスが頻繁に必要 ・オイルミストが飛散し工場の床が滑る ■あるべき姿(理想の条件) ・オイルミストがしっかり捕集され、工場内に飛散しない ・メンテナンス周期も長く、工数がかからない ■アピステのご提案 ・メンテナンス周期の長いミストコレクターGMEシリーズを設置 ■メリット ・メンテナンス周期の長期化による工数削減 ・風量維持により加工機外へのミスト漏れの減少 +α 大幅な省エネを実現(※省エネモード搭載機種) ※詳しくは関連商品カタログをご覧いただくか、お気軽にお問い合わせください。