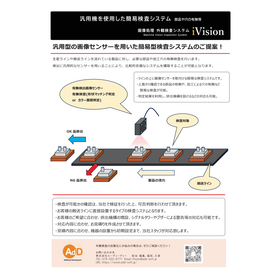

We will automate simple visual inspections such as forgetting to attach parts and the presence or absence of processing holes.

Would you like to automate simple visual inspections by installing a general-purpose image sensor on the conveyor line?

Are you worried about forgetting to attach parts to products flowing on the conveyor line or not having processing holes, and therefore conducting visual inspections, but finding that the cost of introducing automatic inspection equipment is too high? "The inspection itself is not difficult, but it becomes a problem if there is a leak, so we need to assign inspectors. However, we cannot spend nearly 10 million yen on inspection equipment for automation." If you feel this way, please consider us [we are currently offering a guide]. ADDI Co., Ltd. can provide delivery solutions tailored to your needs thanks to our long-standing expertise in the development of inspection equipment. Additionally, our staff will handle installation and initial setup, reducing the burden on our customers. "The inspection content is simple, so we can't spend that much," or "We don't have staff who can handle in-house production." The image processing visual inspection system "iVision" can solve these concerns! *For more details, please download the catalog in PDF format. We will first confirm with you "what" and "in what condition" you want to conduct inspections, consider the appropriate cameras and lighting, and then propose the necessary inspection equipment based on that.

basic information

"Do you have any such issues?" ■ There are cases where defects are overlooked due to visual confirmation by personnel. ■ It takes time to educate on the standards for visual inspection, making it difficult to secure inspectors. ■ We want to automate inspections, but we are worried about whether we can inspect our own products. Our uniquely developed inspection software "iVision" is a product we highly recommend for those considering the automation of visual inspections. "iVision" is a product centered around software, and through full customization, we can accommodate deliveries according to your needs. *For more details, please refer to the PDF materials or feel free to contact us.

Price information

Prices vary significantly depending on the configuration. If you let us know your desired specifications, we will first provide you with a rough estimate.

Delivery Time

Model number/Brand name

Image Processing Visual Inspection System "iVision"

Applications/Examples of results

[Purpose] Checking for the presence or absence of parts and processing holes in products flowing on the conveyor line, etc.

catalog(1)

Download All CatalogsRecommended products

Distributors

◆ Image Processing Inspection System iVision - Supports various inspections such as defect inspection for scratches, chips, and burrs, color tone inspection, character recognition, and dimensional inspection. - A waste-free system through full customization. - Wide range of implementation results in metals, plastics, electronic devices, building materials, textiles, etc. - Compatible with multi-axis robots, 3D sensors, and AI. - Reliable support including setup during installation. ◆ List of Various Sales Software 〇 VariCAD (Low-cost 3D/2D CAD software for mechanical design) 〇 WebDrive (SFTP client compatible with cloud storage) 〇 Titan FTP Server (SFTP server for Windows) 〇 ABBYY FineReader (All-in-one OCR software capable of editing PDF files) 〇 Diff Doc (Document file comparison software)