[Case Study of Solutions] Improvement of Oil Mist Environment at Sites Where Cuttings and Abrasives Occur

We have successfully reduced the maintenance frequency of the mist collector in processes such as polishing, where not only oil mist but also chips and abrasive particles are generated simultaneously.

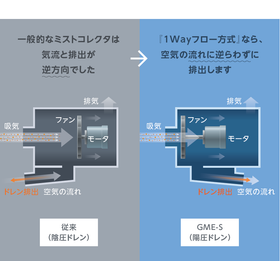

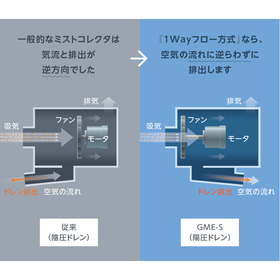

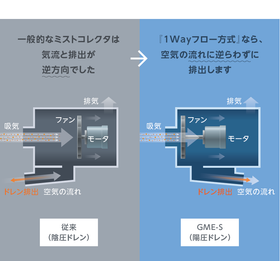

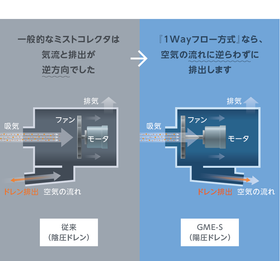

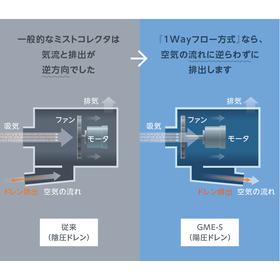

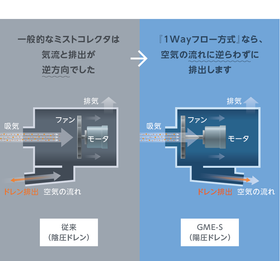

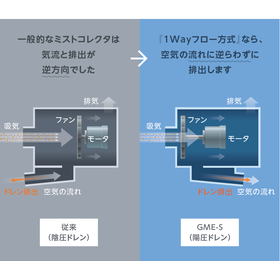

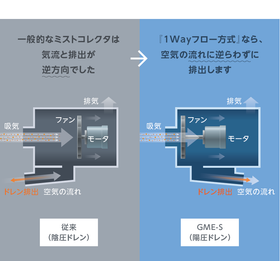

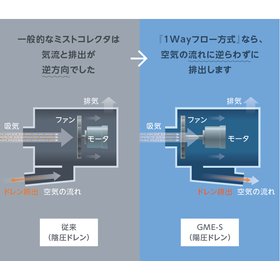

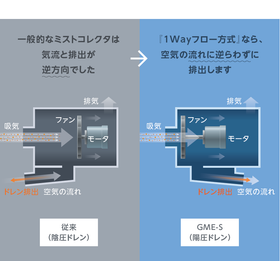

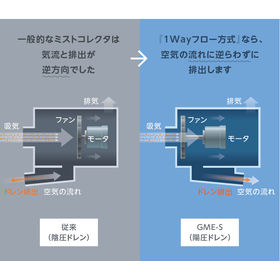

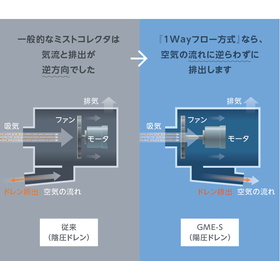

This is an example from a grinding factory. In grinding, not only oil mist but also chips and abrasive particles are generated together. Therefore, traditionally, even if a mist collector was installed, it would quickly become clogged, allowing mist to spread throughout the factory. 【Proposed Solution Example】 ■ Traditional Method - Use of filter-type mist collectors ■ Issues - The mist collector's filter quickly clogs due to the suction of oil mist containing chips and abrasive particles - Frequent maintenance of the mist collector is required - Oil mist disperses, causing odor and haze ■ Ideal Condition - The mist collector's filter does not clog even when sucking in oil mist mixed with chips and abrasive particles - Oil mist is effectively collected and does not disperse within the factory - Longer maintenance cycles with reduced labor ■ Apiste's Proposal - Installation of the GME-S series mist collector, which adopts a "one-way flow system" that does not accumulate chips and abrasive particles internally, allowing for longer maintenance cycles ■ Benefits - Reduction in labor due to extended maintenance cycles - Environmental improvement due to reduced mist leakage outside the processing machine

basic information

This is a case that is possible precisely because Apiste specializes in both environmental improvement and temperature and air conditioning control. Apiste not only handles mist collectors but also dust collectors and air conditioning units, making us proficient in mist and dust countermeasures, as well as protecting equipment and workers. We will propose the optimal improvement methods tailored to each site, so please feel free to contact us. *For more details, please refer to the PDF materials or feel free to contact us.*

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

Detailed information

catalog(1)

Download All CatalogsNews about this product(2)

-

[Improvement Case] The catalog for the GME-S series mist collector, which does not accumulate cut glass or abrasive particles internally with its "One-Way Flow" system, is now available!

This is a case study from a grinding factory made possible by Apiste, which specializes in both environmental improvement and air conditioning/temperature control. Traditionally, even with the installation of mist collectors, filters would quickly become clogged, leading to mist spreading throughout the factory. 【Proposed Solution Case】 ■ Traditional Method - Use of filter-type mist collectors ■ Issues - The filters of the mist collectors quickly clog due to the suction of oil mist mixed with chips and abrasives. - Frequent maintenance of the mist collectors is required. - Oil mist disperses, causing odors and haze. ■ Ideal Condition - Mist collectors do not clog even when sucking in oil mist mixed with chips and abrasives. - Oil mist is effectively collected and does not disperse within the factory. - Longer maintenance cycles with reduced labor. ■ Apiste's Proposal - Installation of the GME-S series mist collector, which employs a "one-way flow method" that does not accumulate chips and abrasives internally, allowing for longer maintenance cycles. ■ Benefits - Reduction in labor due to extended maintenance cycles. - Improvement in the environment due to decreased mist leakage outside the processing machines.

-

[Case Study of Solution Proposal] A mist collector that can continue to capture oil mist mixed with solid particles! The secret to preventing clogs inside is the "one-way flow system."

This is a case study from a polishing factory that can be proposed by Apiste, which specializes in both environmental improvement and air conditioning/temperature control. Traditionally, even with the installation of mist collectors, they would quickly become clogged, allowing mist to spread throughout the factory. 【Solution Proposal Case】 ■ Traditional Method - Use of filter-type mist collectors ■ Issues - Mist collectors clog quickly due to the suction of oil mist mixed with solid particles - Frequent maintenance of mist collectors is required - Oil mist disperses, causing odor and haze ■ Ideal Condition - Mist collectors do not clog even when sucking in oil mist mixed with solid particles - Oil mist is effectively collected and does not disperse within the factory - Longer maintenance cycles with reduced labor ■ Apiste's Proposal - Installation of the GME-S series mist collector with a "one-way flow system" that allows for smooth discharge of solid particles and has a longer maintenance cycle ■ Benefits - Reduction in labor due to extended maintenance cycles - Improved environment due to decreased mist leakage outside of processing machines

Recommended products

Distributors

"Apice," which means "peak" in Spanish. That peak represents "technology" = robust development capabilities, "product" = unmatched high quality, "sincerity" = human service. This spirit, depicted in the clear blue sky, has taken shape in reality, becoming distinctly outlined. And, looking further ahead. What lies in our vision is already the blue sky of the future. Aiming for a new peak.