High-performance filter-type mist collector that can capture even extremely fine mist.

■Collects ultra-fine mist as small as 0.3μm ■No need to replace the filter for a long time ■Only one filter per unit

The "GME-F2200" is a high-performance filter-type mist collector equipped with a smoke catch filter that can capture ultra-fine mist as small as 0.3μm. It maintains high collection efficiency while eliminating the need for filter replacement for an extended period. Additionally, since there is only one filter installed per mist collector, there is no need to replace multiple filters at once. 【Features】 ■ Captures ultra-fine mist as small as 0.3μm ■ High collection efficiency (99.9%) ■ No need for filter replacement for an extended period ■ Only one filter replacement required per unit ■ Easy filter replacement ■ Energy-efficient, using a premium efficiency motor (IE3) *For more details, please refer to the PDF document or feel free to contact us.

basic information

【Features】 ■ Collects ultra-fine mist as small as 0.3μm ■ High collection efficiency (99.9%) ■ No need for filter replacement for a long time ■ Only one filter replacement required per unit ■ Easy filter replacement ■ Energy-saving compatible. Uses a premium efficiency motor (IE3) *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

■Machining Center ■CNC Lathe ■Open-Type Processing Machine ■Piping with Many Branches *For more details, please refer to the PDF document or feel free to contact us.

Detailed information

-

Collects ultra-fine mist of 0.3μm! The smoke catch filter is composed of ultra-fine glass fibers and polyester fibers that support the filter structure, providing high collection efficiency even for extremely small particle sizes. It can be used with peace of mind regardless of equipment, processing methods, types of mist, or particle sizes.

-

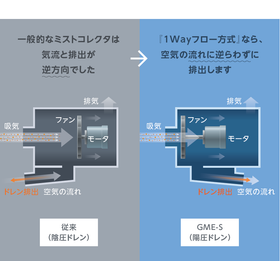

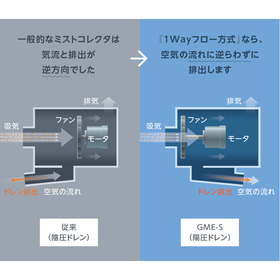

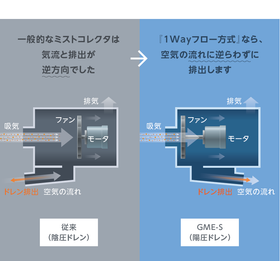

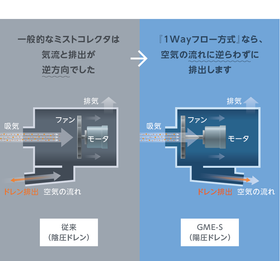

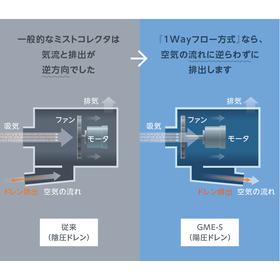

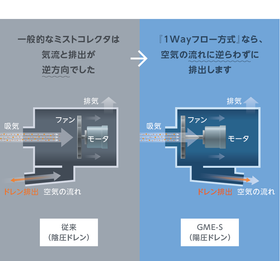

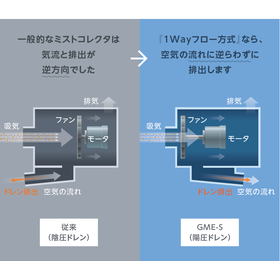

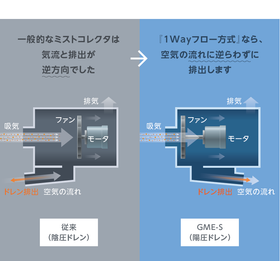

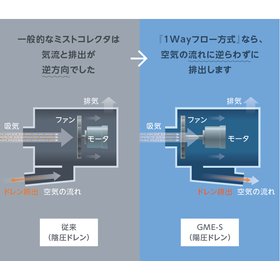

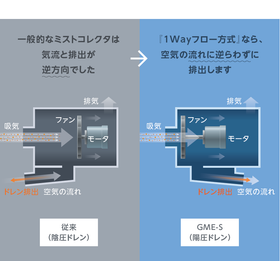

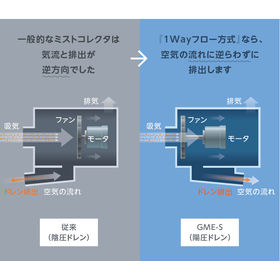

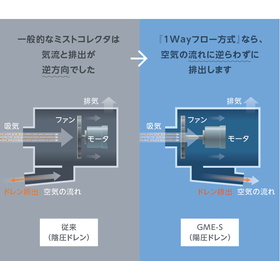

■No need for filter replacement for a long period of time The collected oil mist aggregates and increases in particle size, allowing it to be discharged to the bottom of the filter by its own weight. Additionally, since the direction of oil discharge is perpendicular to the airflow, it is smoothly expelled. This minimizes the re-adhesion of oil mist to the filter, eliminating the need for filter replacement for an extended period.

-

Only one filter can be replaced per unit. Since each mist collector is equipped with only one filter, there is no need to replace multiple filters at once.

catalog(3)

Download All Catalogs

News about this product(3)

-

◆◆Free Progressing◆◆ Latest technical document "Basic Knowledge of Cutting Fluids & Improvement Cases"

Cutting oils are used in machining processes to improve the sharpness of cutting tools, reduce resistance, and extend tool life when cutting metals and other materials. There are various types of cutting oils, each with different characteristics, making it important to choose the right cutting oil for the intended purpose. This document is a comprehensive compilation of knowledge regarding the overview of machining and the essential cutting oils used in the process. Additionally, it explains the types of cutting oils, how to choose them, and measures to prevent health hazards. If you are interested, please download the PDF from the related catalog below or feel free to contact us. [Contents] ■Machining ■Cutting Oils ■How to Choose Cutting Oils ■Cutting Oils and Health Issues

-

◆◆Free Progressing◆◆ Latest technical document "Basic Knowledge of Cutting Fluids & Improvement Cases"

Cutting oils are used in machining processes when cutting metals and other materials to improve the sharpness of cutting tools, reduce resistance, and extend tool life. There are various types of cutting oils, each with different characteristics, making it important to choose the right cutting oil for the intended purpose. This document is a comprehensive compilation of knowledge regarding the overview of machining and the essential cutting oils used in the process. Additionally, it explains the types of cutting oils, how to choose them, and measures to prevent health hazards. If you are interested, please download the PDF from the related catalog below or feel free to contact us. [Contents] ■Machining ■Cutting Oils ■How to Choose Cutting Oils ■Cutting Oils and Health Issues

-

◆◆Free Progressing◆◆ Latest Technical Document "Fundamentals of Cutting Fluids & Improvement Cases"

Cutting oils are used in machining processes to improve the sharpness of cutting tools, reduce resistance, and extend tool life when cutting metals and other materials. There are various types of cutting oils, each with different characteristics, making it important to choose the right cutting oil for the intended purpose. This document is a comprehensive compilation of knowledge regarding the overview of machining and the essential cutting oils used in the process. Additionally, it explains the types of cutting oils, how to choose them, and measures to prevent health hazards. If you are interested, please download the PDF from the related catalog below or feel free to contact us. [Contents] ■Machining ■Cutting Oils ■How to Choose Cutting Oils ■Cutting Oils and Health Issues

Recommended products

Distributors

"Apice," which means "peak" in Spanish. That peak represents "technology" = robust development capabilities, "product" = unmatched high quality, "sincerity" = human service. This spirit, depicted in the clear blue sky, has taken shape in reality, becoming distinctly outlined. And, looking further ahead. What lies in our vision is already the blue sky of the future. Aiming for a new peak.