ENC series coolers for control panels that contribute to the long lifespan of in-panel equipment.

The cooler for control panels will solve your problems with the deterioration and failure of control equipment! [Immediate delivery]

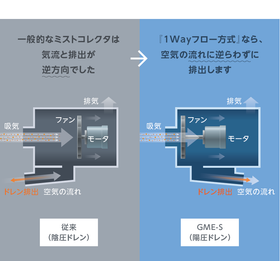

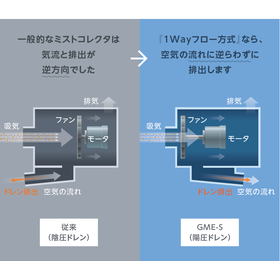

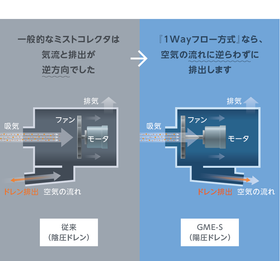

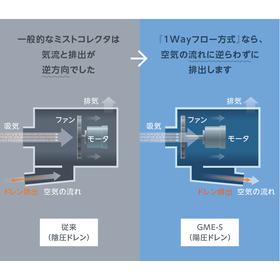

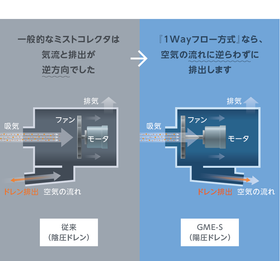

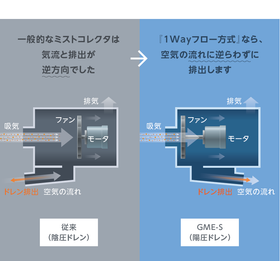

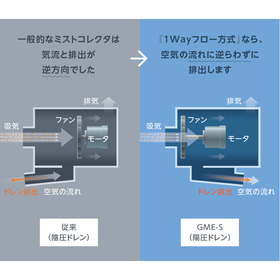

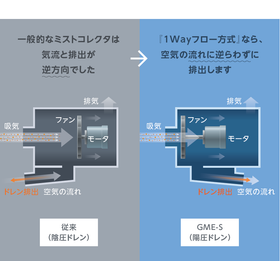

The cooler for control panels that can provide cooling, dehumidification, and dust prevention contributes to the longevity of the equipment inside the panel. By maintaining the condition of the equipment, which is susceptible to heat, stable manufacturing is achieved. ■ For every 10°C increase in temperature, the lifespan is halved <10°C Doubling Rule> Electrolytic capacitors used in electronic devices have their lifespan reduced to half when the ambient temperature rises by 10°C. The cooler for control panels helps keep the internal temperature low, contributing to measures against lifespan reduction due to temperature increases. ■ As the ambient temperature rises, the failure rate increases exponentially <Arrhenius Law> If we assume the relative failure rate of a semiconductor at 40°C is "1", it becomes "10" at 60°C and "100" at 80°C, increasing exponentially. The cooler for control panels helps maintain a low internal temperature, contributing to the stable operation of the manufacturing line. ★ For those with these concerns! Concern 1: I want to cool the inside of the control panel. Due to the summer heat, the control equipment malfunctioned, causing the line to stop and resulting in production losses. Concern 2: I want to seal the control panel for dust prevention and cooling. Oil mist and dust from the factory entered the control panel, causing the inverter and servo amplifier to fail.

basic information

Cooler for Control Panels Suitable for Manufacturing Sites: 'ENC-GR-Pro Series' ■ Significant reduction in maintenance costs and labor with finless and filterless design! The ENC-GR-Pro series adopts a new finless condenser. There are no clogging points, so there is no filter, eliminating the need for filter cleaning or replacement. ■ No management costs for refrigerants as it uses non-fluorocarbon refrigerants! With an extremely low Global Warming Potential (GWP), it is exempt from the Fluorocarbon Emission Control Law, meaning there are no costs for recovering or destroying refrigerants from discarded coolers, and there is no obligation for regular inspections during use. ■ Equipped with an inverter for energy-saving operation The inverter allows operation according to the load rate, achieving up to 55% energy savings compared to our conventional non-inverter products. In addition to "compressor control" using our uniquely developed inverter, it also controls the "condenser fan" and "electronic expansion valve."

Price range

Delivery Time

Applications/Examples of results

■Cooling of Various Control Panels - Cooling of control panels for loading robots - Cooling of welding machine controllers - Cooling of control panels for utility equipment - Cooling of control panels for CNC lathes - Cooling of control panels for straightening machines - Cooling of control panels for machining centers - Cooling of CPU panels for conveying equipment - Cooling of control panels for metal processing lines - Cooling of outdoor control panels - Cooling/dust prevention for control panels in oil mist-heavy environments - Cooling/dust prevention for control panels in dust-heavy environments

Line up(4)

| Model number | overview |

|---|---|

| ENC-GR-Pro | (Non-fluorocarbon, filterless, energy-saving) Zero fluorocarbon management workload with non-fluorocarbon refrigerant specification, no filter replacement needed with finless structure, energy-saving with INV installed. |

| ENC-GR-LE-eco | (Non-Freon, Non-Drain, Energy Saving) Zero Freon management labor with Non-Freon refrigerant specifications, Non-Drain achieved with a special vaporization filter, energy saving with INV equipped. |

| ENC-GR-SUS | (Non-Freon, outdoor specification) Non-Freon refrigerant specification with zero Freon management workload, pursuing durability and high weather resistance with a stainless steel body. |

| ENC-GR-eco | (Non-Freon, energy-saving) Non-Freon refrigerant specification with zero refrigerant management workload, energy-saving with INV equipped. |

catalog(3)

Download All CatalogsRecommended products

Distributors

"Apice," which means "peak" in Spanish. That peak represents "technology" = robust development capabilities, "product" = unmatched high quality, "sincerity" = human service. This spirit, depicted in the clear blue sky, has taken shape in reality, becoming distinctly outlined. And, looking further ahead. What lies in our vision is already the blue sky of the future. Aiming for a new peak.