Case Study on Oil Mist Environment Improvement for Shipbuilding

Solve the oil mist problem at sites where chips and abrasives are generated!

In the shipbuilding industry, oil mist, chips, and abrasives are generated simultaneously during polishing operations, leading to a deterioration of the working environment. The mist collectors often become clogged quickly, resulting in a high frequency of maintenance, which is also a problem. Apiste's mist collectors address these issues and improve the working environment. 【Usage Scenarios】 - Sites where polishing operations are conducted - Environments where oil mist, chips, and abrasives coexist 【Benefits of Implementation】 - Reduction of labor costs due to extended maintenance cycles - Improvement of the environment due to reduced mist leakage outside of processing machines

basic information

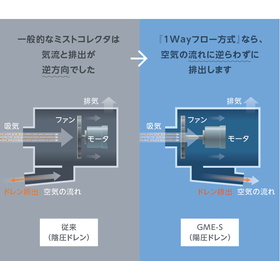

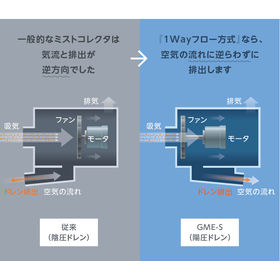

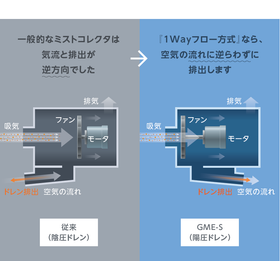

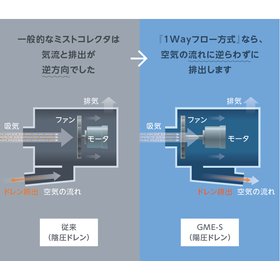

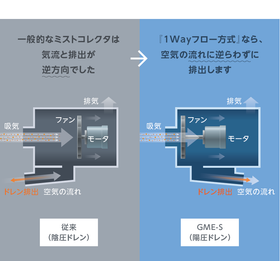

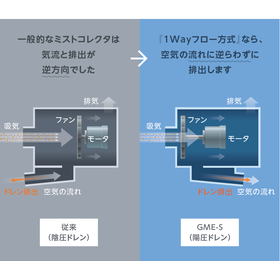

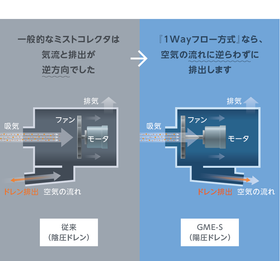

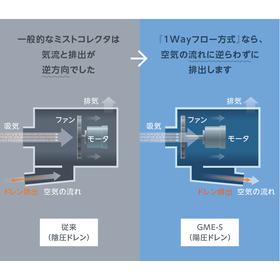

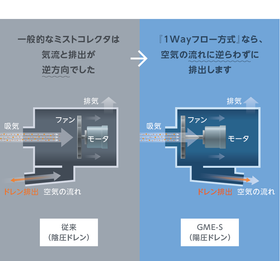

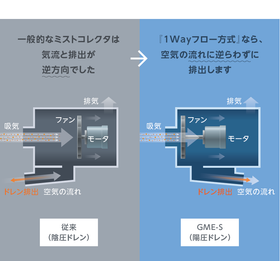

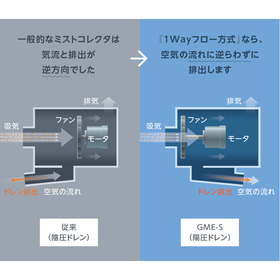

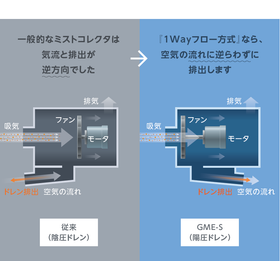

【Features】 - Adopts a "one-way flow system" that does not accumulate chips or abrasive particles inside - Long maintenance cycle - Effectively captures oil mist 【Our Strengths】 We develop and sell environmental improvement equipment, cooling equipment, and temperature control equipment. In addition to mist collectors, we also handle dust collectors and air conditioning units, providing optimal improvement solutions for our customers' sites.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsRecommended products

Distributors

"Apice," which means "peak" in Spanish. That peak represents "technology" = robust development capabilities, "product" = unmatched high quality, "sincerity" = human service. This spirit, depicted in the clear blue sky, has taken shape in reality, becoming distinctly outlined. And, looking further ahead. What lies in our vision is already the blue sky of the future. Aiming for a new peak.