Atmospheric pressure plasma device affects the corrosion and wear resistance of metals.

What influences the corrosion and wear resistance of metals is the "pre-treatment." Atmospheric pressure plasma treatment technology that alters adhesion.

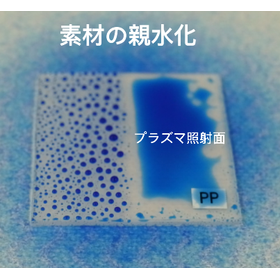

The performance of corrosion and wear resistance treatments through coatings, painting, and adhesion is determined by the condition of the material's surface. Our atmospheric pressure plasma equipment performs non-contact and non-chemical modification treatment on metal surfaces, achieving surface cleaning, activation, and hydrophilicity. This significantly improves the adhesion of coatings, and enhances durability and corrosion and wear resistance. We can conduct evaluation tests and preliminary verifications with test equipment tailored to your work and objectives. After confirming the changes and effects post-treatment, you can consider implementation with confidence. Additionally, we are still in the process of researching special materials and new applications. We aim to deepen and spread our knowledge so that plasma technology can be utilized in more fields. Please feel free to consult us regarding the feasibility of treatments and collaborative discussions.

basic information

Plasma Type: Jet (Remote) Type and Direct Type Plasma Irradiation Width: 25mm to 108mm and Spot Type Processing Gas: Nitrogen Power Supply: AC100V With a non-contact, dry process technology that breaks through the conventional barriers of "cost," "environmental impact," and "material restrictions," your products will begin to create entirely new value starting today. *For more details, please download the PDF or feel free to contact us.

Price range

Delivery Time

Model number/Brand name

Atmospheric pressure plasma device

Applications/Examples of results

First-time one-week free rental service now available. *For more details, please download the PDF or feel free to contact us.

catalog(2)

Download All CatalogsRecommended products

Distributors

Aqua Corporation is a company that focuses on the production of various devices, including equipment for cleaning glass substrates. The devices are primarily custom-made rather than off-the-shelf products, and we manufacture products that meet our customers' needs. We also engage in various resin processing businesses. We have developed our own user-friendly and highly efficient atmospheric pressure plasma equipment and propose and sell applications for new technologies. We provide technical consulting for vacuum equipment, support for maintaining the quality of vacuum film formation, and ensuring stable operation of vacuum devices. For various cleaning devices, resin processing, and atmospheric pressure plasma surface modification equipment, please leave it to us.