Contact angle measurement

By measuring the contact angle with two types of reagents, it becomes possible to analyze the surface free energy of the material.

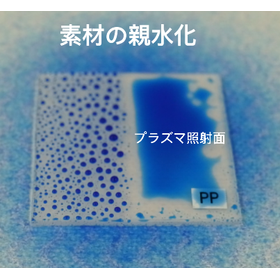

"Contact angle measurement" is a commonly used inspection method to assess the strength of atmospheric pressure plasma effects. A droplet of water is placed on the surface of the target material, and the angle at the point of contact with the material is measured. The smaller the value, the more hydrophilic (the better the affinity for water) the material is. Our company uses the Ellipse (Tangent-1) method, which analyzes the contour of the water droplet by tracing it as separate parts of two ellipses, as the standard analysis method. 【Other Analysis Methods】 ■ 1/2θ Method ■ Tangent Method ■ Young Laplace Method ■ Circle Method *For more details, please download the PDF or feel free to contact us.

basic information

For more details, please download the PDF or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

catalog(1)

Download All CatalogsRecommended products

Distributors

Aqua Corporation is a company that focuses on the production of various devices, including equipment for cleaning glass substrates. The devices are primarily custom-made rather than off-the-shelf products, and we manufacture products that meet our customers' needs. We also engage in various resin processing businesses. We have developed our own user-friendly and highly efficient atmospheric pressure plasma equipment and propose and sell applications for new technologies. We provide technical consulting for vacuum equipment, support for maintaining the quality of vacuum film formation, and ensuring stable operation of vacuum devices. For various cleaning devices, resin processing, and atmospheric pressure plasma surface modification equipment, please leave it to us.