news list

latest news

[11/5 Event: Heat Dissipation Materials Seminar] A networking opportunity with heat management materials suppliers (Tokyo, in-person)

We will hold a "Thermal Material Seminar" for engineers considering the formulation of thermal materials such as electronic materials, adhesives, and ceramics. Participants will have the opportunity t…

91~104 item / All 104 items

-

BYK YouTube additives for thermosetting resins and carbon fiber reinforced resins

You can see the effects of additives on BYK YouTube. Introduction of additives for thermosetting resins and carbon fiber reinforced resins: - Viscosity reduction with BYK-Chemie wetting and dispersing agents; - Viscosity reduction/increased filler concentration with BYK-Chemie wetting and dispersing agents - with animation; - The effect of BYK-C 8013; BYK-C 8013 - coupling agent for carbon fiber reinforced resins.

-

BYK YouTube Explanation of Blocking and Blocking Prevention for Changgan Coatings

You can see the effects of additives on BYK YouTube. Explanation of blocking and blocking prevention of air-drying paint. Paint air-drying paint on paper. After drying, hold the painted paper with the painted side facing inward. Place a weight on top so that the painted surfaces touch each other. Then remove the weight and peel the papers apart. Due to the paint formulation, the painted surfaces stick together, causing damage when peeled apart (blocking). This can be avoided with blocking prevention additives.

-

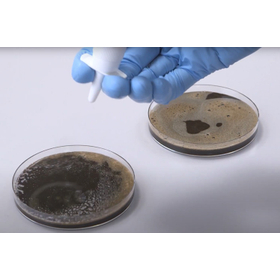

Defoaming of water-based lignosulfonate drilling mud using BYK's Big Chemi defoamer.

You can see the effects of additives on BYK YouTube. Defoaming of water-based lignosulfonate drilling mud using Big Chem defoamer. Foam is generated in the drilling mud by a blender (not shown in the video). Two petri dishes are placed with foamy drilling mud. Defoamer is applied to the drilling mud. The foam disappears immediately.

-

Observation of wetting on base leather with BYK YouTube Big Chemi silicone surface treatment agent.

You can see the effects of additives on BYK YouTube. Observation of wetting on base leather with Big Chemie silicone surface treatment agent. Poor wetting on leather containing mineral oil. Improved wetting tendency on the base with the addition of wetting agents. Two types of water-based blue paint were applied to leather containing a small amount of mineral oil. The paint without additives (left) does not wet. The paint with a polysiloxane-based additive that lowers surface tension (right) shows good wetting on the base.

-

BYK YouTube Big Chemy Synthetic Smectite LAPONITE-EP Dispersion Preparation Method

You can see the effects of additives on BYK YouTube. How to make Big Chemie synthetic smectite LAPONITE-EP dispersion. LAPONITE-EP dispersion in water Method for preparing LAPONITE-EP dispersion in the laboratory.

-

BYK YouTube Big Chemi additive ease of cleaning. Carbon particle dust.

You can see the effects of additives on BYK YouTube. Cleaning properties with Big Chemie additives. Carbon particle dust. Ease of cleaning with epoxy system: without epoxy coating additives (left) and with BYK-SILCLEAN 3701 additive (right). Carbon dust is sprinkled on the panel. The right side (with additive) can be easily washed off. The left side (without additive) cannot be sufficiently cleaned.

-

BYK YouTube Easy cleanability with epoxy using Big Chemi additives. Water-based carbon slurry.

You can see the effects of additives on BYK YouTube. Easy cleanability with epoxy using Big Chemie additives. Water-based carbon slurry. Epoxy paint without additives (left) and with BYK-SILCLEAN 3701 additive (right). Water-based carbon slurry applied to the panel. After drying: right (with additive) can be easily cleaned; left (without additive) cannot be cleaned.

-

BYK YouTube Observation of Silica Dispersion in Epoxy by Big Chemie

You can see the effects of additives on BYK's YouTube. Observation of silica dispersion in epoxy by Big Chemie. Firing silica is stirred and mixed into epoxy resin with a dissolver. Hydrophilic silica (right) mixes faster than hydrophobic silica (left).

-

BYK YouTube demonstration of foaming paint at Big Chemie.

You can see the effects of additives on BYK's YouTube channel. Demonstration of foam paint at Bic Chemical. Using two cans to demonstrate the role of foam paint: one can is coated with regular direct metal paint and the other with fire-resistant foam paint. The cans are stacked with metal blocks to apply pressure, allowing flames to reach the paint film. The regular paint film deteriorates until the can bursts, and high temperatures weaken the metal, while the foam paint prevents the can from bursting through expansion and the formation of char.

-

BYK YouTube Scratch Test of Plastek at Big Chemie

You can see the effects of additives on BYK YouTube. Scratch test of Plastek at Big Chemie. Scratch test of Plastek material. Using a Taber abrasion testing machine, the scratch resistance of Plastek material is evaluated. Additives improve scratch resistance.

-

BYK YouTube Defoaming with Big Chemi Floor Epoxy

You can see the effects of additives on BYK YouTube. Defoaming with Big Chemie floor epoxy. Defoaming and bursting of bubbles during the application of floor epoxy. - Floor painting with a self-leveling towel that has cuts. Bubbles are trapped and remain in the coating. The defoamer instantly eliminates the bubbles.

-

BYK YouTube Big Chemie Silicone-based Additives in Different Solvents

You can see the effects of additives on BYK YouTube. Behavior of polysiloxane-based additives in three different solvents - After shaking three types of solvents (ethanol, xylene, butyl acetate), no foam remains. A certain amount of silicone-based additive (BYK-323) is added to each solvent. After shaking, the left bottle is cloudy, the middle bottle is clear but foams strongly, and the right side is clear with no foam. The effectiveness of silicone-based surface modifiers strongly depends on the compatibility in the solution state.

-

BYK YouTube 【BYK】RCA wear test at Big Chemie

You can see the effects of additives on BYK's YouTube channel. 【BYK】RCA wear test at Bic Chemie The impact of additives such as wax on the abrasion resistance of coatings. Evaluation method using the RCA wear testing machine (Wazau test) - Two samples coated on a glass plate are evaluated. A paper with abrasives is pulled across the coating surface with a constant pressure. After pulling for 10 cm, the coating is completely scraped off. In systems where wax is blended to improve abrasion resistance, the distance increases from 10 cm to 80 cm. At 10 cm, almost no wear is observed, while at 80 cm, the condition is better than that of the control at 10 cm.

-

BYK YouTube 【BYK】Stabilization Observation of Foam by Big Chemie A

You can see the effects of additives on BYK YouTube. 【BYK】Observation of foam stabilization by BIC Chemical A Foam does not form in pure water. - Foam in clean water. The foam disappears immediately after reaching the surface. There is no stable foam. There is no foam in clean liquid.