Foundry services for autonomous driving

Supporting autonomous driving with multi-variety, high-precision, proposal-based foundry services.

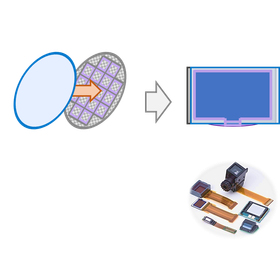

As autonomous driving technology evolves, the automotive industry requires high-precision sensors and displays. These devices demand miniaturization, high resolution, and high reliability. Foundry services contribute to the performance enhancement of autonomous driving systems by undertaking the production of liquid crystal microdisplays to meet these needs. 【Application Scenarios】 - In-vehicle displays - LiDAR - Head-up displays 【Benefits of Implementation】 - Provision of high-precision devices - Realization of miniaturization and lightweight design - Flexible response to custom specifications

basic information

【Features】 - Comprehensive support from LCD panel assembly to circuit board mounting - Compatible with various modes such as LCOS and FLC - Proven track record in narrow GAP and miniaturization - Supports 6 to 12-inch wafers - Capable of inorganic vertical alignment with owned deposition equipment 【Our Strengths】 Citizen Fine Devices leverages its long-established manufacturing technology for small precision components to provide high-precision microdevices. We have a consistent production system that covers process design, machining, assembly, and functional testing, and we flexibly accommodate custom specifications tailored to our customers' needs.

Price range

Delivery Time

Applications/Examples of results

The contract manufacturing market for semiconductor and optical devices relies on customizability as the key to competitiveness. Demand for foundry services is projected to grow at an annual rate of 15% by 2026. WSS (Wavelength Selective Switch) HUD, MHD Optical communication equipment.

catalog(1)

Download All CatalogsRecommended products

Distributors

The area where Citizen Fine Devices demonstrates its strength is in the realm of functional components that require small size, precision, high accuracy, and high detail. We believe that our mission is to continue providing high-value-added microdevice products by leveraging the unique technologies we have developed over many years. Utilizing metal processing technology rooted in watch manufacturing, we have consistently supplied small, high-precision components to our customers for many years through a fully integrated production line that encompasses process design, machining, assembly, and functional testing, along with the unique development of our own processing machines. Additionally, mass-producing components with high precision and efficiency using brittle materials is also one of our core technologies. By integrating material technology with ultra-precision machining, thin-film technology, and bonding technology, we produce not only high-precision components such as ceramics and quartz but also high-quality functional device products like liquid crystal devices and sensing devices. Continuing to provide high-value-added products to the market is a significant dream for our employees. We will contribute to the creation of new value through manufacturing driven by the challenge spirit of each individual, working towards the realization of that dream.