Failure analysis of electronic devices and components

From investigating the mechanisms of failures and malfunctions to proposing improvement measures and verifying their effectiveness, our expert engineers provide total support!

Eurofins FQL provides failure analysis for a variety of products, from circuit components such as semiconductors, printed circuit boards, and connectors to OEM and ODM products. If you have concerns such as "I want to conduct failure analysis but do not have sufficient equipment" or "I have doubts about the manufacturer's failure analysis report," please feel free to contact us. 【Leave it to us】 ■ Investigation Plan: Understanding failure phenomena and planning analysis methods to confirm usage conditions ■ Non-destructive Analysis: Narrowing down abnormal areas non-destructively ■ Destructive Analysis: Estimating causes through observation and analysis of the occurrence of abnormalities ■ Summary of Results: Summarizing analysis results and proposing improvements *For more details, please refer to the PDF materials or feel free to contact us.

basic information

Feasible Failure Analysis ■ Non-destructive Analysis - Confirmation of electrical characteristics - Inspection of abnormal areas and internal structure ■ Destructive Analysis - Observation of abnormal areas - Opening of package resin - Material analysis

Price information

For more details, please contact us.

Delivery Time

Applications/Examples of results

We have numerous achievements beyond those listed below. For more details, please contact us. - LCD panel failure analysis - Communication module failure analysis - Power module failure analysis - MOSFET failure analysis - DC-DC converter failure analysis - Operational amplifier failure analysis - Choke coil failure analysis - SSD failure analysis - Power supply unit failure analysis

catalog(12)

Download All CatalogsNews about this product(4)

-

Supply disruptions from semiconductor manufacturers, the electrification of the automotive industry, and the spread of 5G communication. Are you keeping up with the urgent need for alternative product evaluations, authenticity assessments, and failure analysis?

The spread of 5G communication, the electrification of the automotive industry, the intensification of US-China trade friction represented by certain semiconductor manufacturers leading to supply stoppages, and the rapid increase in digital products due to the impact of the COVID-19 pandemic are various social phenomena that are increasing the demand for semiconductors. Along with these developments, the acceleration of semiconductor supply risks is progressing. In addition to the adoption of new products, evaluation of existing and distributed products is also necessary... However, the personnel involved in new adoption and product evaluation are limited. Do you have any of these concerns? - Lack of know-how to evaluate semiconductor components - Want to evaluate alternative products but lack personnel and equipment - Want to use stock items and market products but have concerns about reliability - Unable to determine whether the delivered semiconductor products are counterfeit or genuine At Eurofins FQL, we leverage our years of experience in component evaluation and failure analysis to provide not only semiconductor evaluations but also failure analysis services. Additionally, we offer evaluations of distributed products to assist in determining the authenticity of counterfeit, imitation, or long-term stored items. Please feel free to contact us.

-

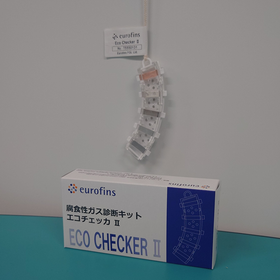

[Free Seminar] Corrosion Environment Solutions for Ensuring Reliability and Longevity of Electronic Equipment and Facility Maintenance (Introduction of Corrosion Environment Diagnosis Kit Eco Checker II)

The usage environment of electronic devices varies, and the impact of corrosion caused by various environmental factors tends to increase. The reliability and lifespan of electronic devices heavily depend on the environment in which they are used. Corrosive substances originating from hot springs, volcanoes, waste, and rivers can corrode electronic components, printed circuit board wiring, connector contacts, and switch contacts of electrical equipment, potentially leading to serious issues. This content is recommended for those who want to solve such challenges: • Does the atmosphere of the operating environment lead to failures in electronic devices? • I want to reduce the risk of failure in harsh environments such as hot springs and wastewater treatment plants. • I want to conduct environmental surveys in large factories with fewer personnel and man-hours. • I want to prolong the lifespan of aging infrastructure as much as possible. We will introduce our original corrosion environment diagnostic kit, Eco Checker II, as well as methods for diagnosing corrosion environments.

-

54th Reliability, Maintainability, and Safety Symposium | Introduction of Case Studies on the Shortened Lifespan of Pogo Pins

We will be exhibiting at the 54th Reliability, Maintainability, and Safety Symposium. ■Content We will present a case study focusing on market failures that resulted from contact failure due to corrosion (dezincification) occurring inside pogo pins. Additionally, we conducted verification on new samples based on four key points extracted from FTA (corrosive substances, temperature/humidity, scratches (wear), and pinholes), and found that the presence of formate ions and sulfate ions, along with scratches (wear), significantly accelerated corrosion. We will estimate the contact failure mechanism derived from the verification results.

-

[Free Seminar] Corrosion Issues of Electronic Components - Evaluation and Countermeasures -

The spread of DX (Digital Transformation) has led to an increase in electronic devices and equipment across various fields. As DX progresses, the opportunities for these devices to be used in diverse environments are increasing, and quality issues due to corrosion are becoming a significant challenge. The digitization of business processes in factories, infrastructure, agriculture, and healthcare is expanding the installation of electronic devices such as IoT sensors, edge devices, and network equipment. These devices are often placed not only in ideal indoor environments but also in harsh conditions, which amplifies the impact of corrosion. In this seminar, we will provide a concrete explanation using examples of evaluation, analysis, and countermeasures against troubles caused by corrosion. This is recommended for those facing the following quality issues: - Connection failures and short circuits - Deterioration of electronic devices - Shortened product lifespan - Corrosion prevention measures

Recommended products

Distributors

Eurofins FQL Co., Ltd. has its origins in the analysis division of Fujitsu Laboratories Ltd. and the quality assurance department of Fujitsu Ltd. It has long engaged in activities aimed at improving product quality, not only in material analysis, reliability evaluation, safety assessment, and failure analysis, but also in supplier quality management and manufacturing plant audits. Additionally, it contributes to solving challenges faced by organizations responsible for quality through the development and educational support of personnel involved in quality, as well as the construction and improvement of quality management, product chemical substance management systems, and software development processes. ■ Reliability Evaluation and Environmental Testing Various reliability evaluations, safety verification of secondary batteries and power supplies, etc., including smoke and fire hazards. Evaluation of special environments such as weather resistance and gas corrosion. ■ Failure Analysis Failure analysis of electronic components and devices, confirmation of characteristics related to materials, and detailed analysis of defects. ■ Support for Building and Improving Quality-Related Systems and Processes To achieve QCD (Quality, Cost, Delivery) goals, we support the improvement of development processes using models such as CMMI and Automotive SPICE. ■ Quality-Related Education Customized educational programs tailored to specific challenges, such as "I want to revitalize the organization," "I want to cultivate a quality mindset," and "I want to provide quality education for new employees."