Support for the establishment and improvement of Quality Management Systems (QMS)

We will support the creation of a system that achieves product quality leading to customer satisfaction!

We assist in ensuring the quality of your products by reviewing the manufacturing process in response to quality issues such as recalls due to design flaws or component defects, frequent problems in the manufacturing process, and delays in product shipments caused by material procurement issues. This includes detecting issues in the operation of the quality assurance system and its mechanisms, as well as providing support for problem-solving (improvement support). Additionally, we offer educational programs to further strengthen the quality assurance system. *For more details, please refer to the PDF materials or feel free to contact us.

basic information

【Service Highlights】 ■ Leads to gaining customer trust - By establishing and improving a quality assurance system, "product quality enhancement" and "stable product supply to the market" increase customer trust. ■ Implementation of education for problem-solving such as "5 Whys Analysis" (human resource training) ■ Basics of Quality Management System (QMS) (E-learning) *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(3)

Download All CatalogsNews about this product(2)

-

Silent change, resurgence. Concerns about the safety and reliability of market-distributed products. How to prevent recalls?

Unstoppable battery fires. Chaos from semiconductor supply shortages. How can we identify poor-quality products and prevent recalls? Poor-quality products are not limited to batteries frequently covered by the media, but also include OEM products, semiconductors that are in short supply, and a wide range of connectors and cables that users prioritize for appearance and price. Suppliers of products need to thoroughly evaluate the components and materials used in their products to ensure quality. However, it is common for manufacturers to change parts and usage without notice, leading to defective products entering the market unnoticed, which can trigger product accidents. Key points to prevent recalls include: - Product evaluation and safety assessment at the time of adoption - Confirmation of supplier quality assurance systems at the time of adoption - Verification of sales through legitimate domestic channels - Regular checks for silent changes Eurofins FQL has been involved in product quality assurance for a long time. Leveraging that expertise, we offer services for safety evaluations of batteries, identification of poor-quality products, and factory audits from the perspective of managing upstream quality.

-

Seminars and E-learning on Quality, Technology, and Process Improvement

We provide various educational services that our clients' organizations desire, such as "holding face-to-face/online seminars to acquire necessary knowledge for business, including root cause analysis and 8D reports," "dispatching instructors for quality education for new employees," "providing e-learning to foster a quality mindset," and "holding workshops to energize the organization." ■Examples of Target Themes■ - Introduction to Automotive SPICE V4.0 Course - Process-Oriented Root Cause Analysis - Introduction to 8D Report Course - STAMP/STPA Seminar - Software Quality Management Training - Introduction to Software Configuration Management - Basics of Quality Management System (QMS) - Basics of Managing Chemical Substances in Products *We accept not only new seminars but also the development of teaching materials, regardless of the delivery method, such as face-to-face or e-learning. *Our seminars are intended for corporate clients. We do not accept individual applications. *Automotive SPICE is a registered trademark of VDA.

Recommended products

Distributors

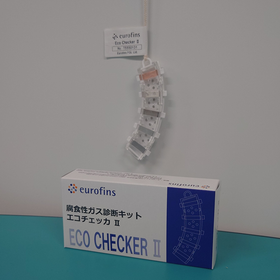

Eurofins FQL Co., Ltd. has its origins in the analysis division of Fujitsu Laboratories Ltd. and the quality assurance department of Fujitsu Ltd. It has long engaged in activities aimed at improving product quality, not only in material analysis, reliability evaluation, safety assessment, and failure analysis, but also in supplier quality management and manufacturing plant audits. Additionally, it contributes to solving challenges faced by organizations responsible for quality through the development and educational support of personnel involved in quality, as well as the construction and improvement of quality management, product chemical substance management systems, and software development processes. ■ Reliability Evaluation and Environmental Testing Various reliability evaluations, safety verification of secondary batteries and power supplies, etc., including smoke and fire hazards. Evaluation of special environments such as weather resistance and gas corrosion. ■ Failure Analysis Failure analysis of electronic components and devices, confirmation of characteristics related to materials, and detailed analysis of defects. ■ Support for Building and Improving Quality-Related Systems and Processes To achieve QCD (Quality, Cost, Delivery) goals, we support the improvement of development processes using models such as CMMI and Automotive SPICE. ■ Quality-Related Education Customized educational programs tailored to specific challenges, such as "I want to revitalize the organization," "I want to cultivate a quality mindset," and "I want to provide quality education for new employees."