Automotive components, automotive units, evaluation and analysis, A-SPICE compliance.

We accept evaluation testing and failure analysis of automotive electronic components and electronic devices.

Electronic components and devices installed in vehicles, including ECUs, are expected to be used in harsh environments. Various requirements from international standards (such as IEC-Q100, VDA, IATF16949) as well as unique standards from domestic and international automobile manufacturers are imposed on installed parts and units. On the other hand, in the development of in-vehicle software, there is an increasing need to comply with 'ASPICE', a development process model specialized for the automotive industry, and cases where this becomes a new ordering condition are also on the rise. For in-vehicle components and devices, we offer services for various reliability evaluation tests, environmental tests, durability tests, and failure analysis as required. In software development, we provide support for building development processes that comply with ASPICE and educational programs that explain the requirements of ASPICE.

basic information

Weather Resistance Testing SAE J2527 - Society of Automotive Engineers Standard ASTM G115 - American Society for Testing and Materials Standard JIS K 7350-2 - Japanese Industrial Standard ISO 4892-2 - International Organization for Standardization Standard IEC J60950-1 Annex Y4892-2 - International Electrotechnical Commission Standard Gas Corrosion Testing JIS C 60068-2-42 - Environmental Testing Methods - Electrical and Electronic - Sulfur Dioxide Test Method for Contacts and Connections JIS C 60068-2-43 - Environmental Testing Methods - Electrical and Electronic - Hydrogen Sulfide Test Method for Contacts and Connections JIS C 60068-2-60 - Environmental Testing Methods - Electrical and Electronic - Mixed Gas Flow Corrosion Test Reduced Pressure Testing JIS C 60068-2-13 - Environmental Testing Methods - Electrical and Electronic - Reduced Pressure Test Method JIS C 8712 - Safety of Sealed Small Secondary Batteries UL1642 - Lithium Batteries Thermal Shock Testing / Temperature and Humidity Environmental Testing IEC / JIS C 60068-2-30 - Environmental Testing Methods - Electrical and Electronic - Temperature and Humidity Cycle Test Method IEC / JIS C 60068-2-78 - Environmental Testing Methods - Electrical and Electronic - High Temperature and High Humidity Test Method Others

Price range

Delivery Time

Applications/Examples of results

■ Reliability Evaluation Testing - Screening of mass-produced automotive ECUs in low/high temperature environments - Weather resistance testing of headlamps (ISO 17025 compliant) - Various reliability tests for semiconductors (IC, LSI) based on AEC-100 ■ Failure Analysis - Chemical crack fracture surface analysis of molded case resin materials - Surface analysis of abnormal areas (rust) in rush adjusters ■ Software Development Related - Support for building ASPICE processes (software development processes)

catalog(16)

Download All CatalogsNews about this product(2)

-

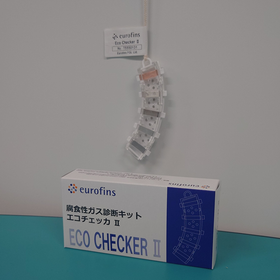

[Free Seminar] Corrosion Environment Solutions for Ensuring Reliability and Longevity of Electronic Equipment and Facility Maintenance (Introduction of Corrosion Environment Diagnosis Kit Eco Checker II)

The usage environment of electronic devices varies, and the impact of corrosion caused by various environmental factors tends to increase. The reliability and lifespan of electronic devices heavily depend on the environment in which they are used. Corrosive substances originating from hot springs, volcanoes, waste, and rivers can corrode electronic components, printed circuit board wiring, connector contacts, and switch contacts of electrical equipment, potentially leading to serious issues. This content is recommended for those who want to solve such challenges: • Does the atmosphere of the operating environment lead to failures in electronic devices? • I want to reduce the risk of failure in harsh environments such as hot springs and wastewater treatment plants. • I want to conduct environmental surveys in large factories with fewer personnel and man-hours. • I want to prolong the lifespan of aging infrastructure as much as possible. We will introduce our original corrosion environment diagnostic kit, Eco Checker II, as well as methods for diagnosing corrosion environments.

-

[Free Seminar] Key Changes from Automotive SPICE V3.1 to V4.0

As competition in the automotive industry intensifies, the importance of software development quality and process improvement is increasingly recognized. In this webinar, we will introduce the "Automotive SPICE" seminar and process improvement support solutions provided by Eurofins FQL, and explain the changes from Automotive SPICE V3.1 to V4.0. Target Audience: - Those considering or interested in responding to Automotive SPICE - Those contemplating an upgrade from Automotive SPICE V3.1 to V4.0 - Those who want to confirm the changes from Automotive SPICE V3.1 to V4.0 *Attendance from competing companies is not permitted. Program: 1. What is Automotive SPICE? Overview of the process improvement framework in the automotive industry Additions, changes, and points of caution from V3.1 to V4.0 2. Introduction to Eurofins FQL's services Automotive SPICE introductory course Support for building processes compliant with Automotive SPICE

Recommended products

Distributors

Eurofins FQL Co., Ltd. has its origins in the analysis division of Fujitsu Laboratories Ltd. and the quality assurance department of Fujitsu Ltd. It has long engaged in activities aimed at improving product quality, not only in material analysis, reliability evaluation, safety assessment, and failure analysis, but also in supplier quality management and manufacturing plant audits. Additionally, it contributes to solving challenges faced by organizations responsible for quality through the development and educational support of personnel involved in quality, as well as the construction and improvement of quality management, product chemical substance management systems, and software development processes. ■ Reliability Evaluation and Environmental Testing Various reliability evaluations, safety verification of secondary batteries and power supplies, etc., including smoke and fire hazards. Evaluation of special environments such as weather resistance and gas corrosion. ■ Failure Analysis Failure analysis of electronic components and devices, confirmation of characteristics related to materials, and detailed analysis of defects. ■ Support for Building and Improving Quality-Related Systems and Processes To achieve QCD (Quality, Cost, Delivery) goals, we support the improvement of development processes using models such as CMMI and Automotive SPICE. ■ Quality-Related Education Customized educational programs tailored to specific challenges, such as "I want to revitalize the organization," "I want to cultivate a quality mindset," and "I want to provide quality education for new employees."