Yearly increasing battery fire incidents. Free distribution of safety evaluation guidebook!

Prevent smoke and fire accidents and short lifespan in advance! We offer safety evaluations for secondary batteries, power supplies, AC adapters, noise tolerance assessments, and characteristic evaluations.

Accidents involving products equipped with lithium-ion batteries, such as mobile batteries, are increasing year by year. There are calls for caution regarding the rise in fire incidents caused by lithium-ion batteries due to high temperatures. Lithium-ion batteries are composed of flammable materials and inherently carry the risk of smoke and fire. As secondary batteries have rapidly proliferated, fire incidents have also been on the rise each year. This is not only due to the harshening of usage environments and mechanisms but also because the risks of smoke and fire have not been fully verified. As a third-party verification of battery units, we assess battery performance through tests different from PSE testing: - Nail penetration test (simulating internal short circuits to assess performance) - Heating limit test (heating to thermal limits to assess performance) - 0V charging prohibition protection (assuming recharging after long-term storage) Do you have any of these concerns? - I recognize that it is dangerous, but I don't know what to do. - I lack experience and know-how in evaluation, and I am anxious about ensuring safety. - I want to determine not only safety but also whether the battery has characteristics suitable for the product. - I want to evaluate the product's durability against high temperatures, drops, and impacts to prevent fire incidents in the market.

basic information

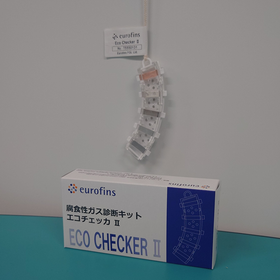

■Main Services - Safety evaluation, lifespan testing, and characteristic evaluation of battery units (Safety evaluation of battery cells, verification of battery pack protection circuits, lifespan and characteristic evaluation) - Reliability evaluation (Lifespan testing/characteristic evaluation of batteries, application evaluation tests that cannot be handled by existing equipment) - Safety evaluation tests for power units and AC adapters, noise tolerance evaluation, characteristic evaluation ■Main Equipment - Battery test system (charge/discharge tester) Charge and discharge cycle testing for batteries (including lead batteries) Customizable specifications can be set as needed Automatic cycle testing possible through program settings - Advanced Safety Tester (ADST) Safety evaluation of secondary batteries External short circuit, temperature (-40 to +100°C) Internal short circuit (nail penetration test), external pressure (crush test)

Price range

Delivery Time

Model number/Brand name

Battery (secondary battery), AC adapter, safety evaluation tests for power supply, noise tolerance evaluation, characteristic evaluation. Analysis of defects such as burning, smoking, ignition, and short lifespan.

Applications/Examples of results

For more details, please download the brochure or contact us.

Related Videos

Line up(7)

| Model number | overview |

|---|---|

| Power supply and battery-equipped product standard testing agency service | We undertake various public standard tests applicable to household and commercial electrical products (JIS, UL, IEC, etc.). |

| Evaluation and Failure Analysis of Power Supply / AC Adapter | Extract and propose appropriate reliability evaluation and testing content from the anticipated failure modes. |

| Investigation and analysis of causes of smoke generation, ignition, and burning damage. | Commissioned to investigate the causes of smoke, fire, and burn damage in electrical and electronic products. |

| Evaluation of the lifespan and deterioration diagnosis of market operating devices and equipment. | Visualizing and quantifying the degree of degradation and remaining lifespan of equipment and facilities that are currently in operation or use in the field. |

| Applied contract testing (reliability evaluation testing, environmental testing, failure reproduction testing) | By coordinating with physical wiring switching circuits and various sensors, it enables the implementation of complex reliability evaluation tests, environmental tests, and reproducibility tests that cannot be conducted with conventional testing machines. |

| Quality assurance of OEM products, supplier management, market research. | We undertake part of the supplier quality management tasks, such as quality confirmation of OEM products from supplier factory audits and market research to assist in determining the authenticity of market products. |

| Support for Automotive SPICE process development | The Battery Management System (BMS) is particularly important in electric vehicles. It strongly requires an understanding of Automotive SPICE as a compliance requirement for in-vehicle software development, and supports the construction of development processes. |

catalog(8)

Download All CatalogsNews about this product(3)

-

Silent change, resurgence. Concerns about the safety and reliability of market-distributed products. How to prevent recalls?

Unstoppable battery fires. Chaos from semiconductor supply shortages. How can we identify poor-quality products and prevent recalls? Poor-quality products are not limited to batteries frequently covered by the media, but also include OEM products, semiconductors that are in short supply, and a wide range of connectors and cables that users prioritize for appearance and price. Suppliers of products need to thoroughly evaluate the components and materials used in their products to ensure quality. However, it is common for manufacturers to change parts and usage without notice, leading to defective products entering the market unnoticed, which can trigger product accidents. Key points to prevent recalls include: - Product evaluation and safety assessment at the time of adoption - Confirmation of supplier quality assurance systems at the time of adoption - Verification of sales through legitimate domestic channels - Regular checks for silent changes Eurofins FQL has been involved in product quality assurance for a long time. Leveraging that expertise, we offer services for safety evaluations of batteries, identification of poor-quality products, and factory audits from the perspective of managing upstream quality.

-

Caution regarding fire incidents caused by products using lithium-ion batteries. Are the standards tests and safety evaluations for electrical products sufficient?

Products that use lithium-ion batteries and are worn or carried in daily life. It is important to conduct thorough evaluations during the product design phase, rather than relying solely on consumers' charging conditions, impacts, and disposal methods for safety. Eurofins FQL offers services including fire analysis of wireless earphones, smartwatches, portable fans, and mobile batteries (note that analysis may not be possible for severely damaged items), battery safety evaluations, and safety assessments of battery-powered devices such as home appliances (including circuit verification) and analysis services. We are here to help ensure thorough evaluations of products to prevent accidents before they occur. Please feel free to consult with us.

-

Scheduled to be operational in January 2026 for automotive and mobility applications. Introduction of smoke and fire testing equipment capable of testing battery capacities of 50Ah!

The battery safety evaluation tests, which receive a lot of inquiries. The Advanced Safety Tester is a device capable of conducting various tests, including the nail penetration test (a test to confirm whether internal short circuits caused by various factors will lead to smoke or fire by forcibly short-circuiting the battery internally with a nail), overcharge tests, and external short circuit tests. We will introduce equipment that supports battery capacities of up to 50Ah, further enhancing the size and durability of battery facilities! ■ Nail Penetration Test | Specifications Battery Capacity Expansion: Up to 50Ah Battery Type Expansion: Single cell, module, pack state, product state Test Item Expansion: Various safety tests + fire spread tests possible Temperature Control: -30℃ to +100℃ Nail Penetration Speed: 0.1 to 150mm/s (Stroke 0.1mm) Crush Load Variable: 0.5k to 20kN * We will flexibly respond to various requests such as witnessing tests and providing videos. Please feel free to contact us!

Recommended products

Distributors

Eurofins FQL Co., Ltd. has its origins in the analysis division of Fujitsu Laboratories Ltd. and the quality assurance department of Fujitsu Ltd. It has long engaged in activities aimed at improving product quality, not only in material analysis, reliability evaluation, safety assessment, and failure analysis, but also in supplier quality management and manufacturing plant audits. Additionally, it contributes to solving challenges faced by organizations responsible for quality through the development and educational support of personnel involved in quality, as well as the construction and improvement of quality management, product chemical substance management systems, and software development processes. ■ Reliability Evaluation and Environmental Testing Various reliability evaluations, safety verification of secondary batteries and power supplies, etc., including smoke and fire hazards. Evaluation of special environments such as weather resistance and gas corrosion. ■ Failure Analysis Failure analysis of electronic components and devices, confirmation of characteristics related to materials, and detailed analysis of defects. ■ Support for Building and Improving Quality-Related Systems and Processes To achieve QCD (Quality, Cost, Delivery) goals, we support the improvement of development processes using models such as CMMI and Automotive SPICE. ■ Quality-Related Education Customized educational programs tailored to specific challenges, such as "I want to revitalize the organization," "I want to cultivate a quality mindset," and "I want to provide quality education for new employees."