Connector and cable evaluation/failure analysis service

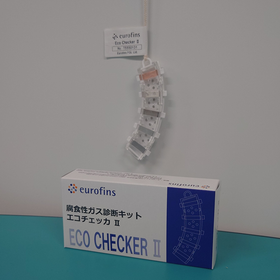

In addition to failure analysis, evaluation tests focusing not only on environmental resistance (temperature, humidity, gas, saltwater) but also on mechanical performance, physical performance, and electrical performance were conducted.

It is an electrical component and a mechanical component. Connectors that combine both functions require evaluation tests focusing not only on environmental resistance (temperature, humidity, gas, saltwater) but also on mechanical performance, physical performance, and electrical performance. Eurofins FQL offers product quality evaluations and long-term reliability assessments according to standards. Failure analysis services are also available.

basic information

Reliability Assessment Whisker Evaluation, Micro-Vibration Test (Hammering Method) Quality Evaluation Cable Terminal Crimping Condition (Cross-Section Observation) Analysis Related Red Phosphorus Content Analysis, Gold-Plated Terminal Analysis

Price information

For more details, please contact us.

Delivery Time

Applications/Examples of results

Reliability evaluation and failure analysis of mechanical components such as connectors, cables (harnesses), sockets, card slots, and switches.

catalog(13)

Download All CatalogsNews about this product(3)

-

Silent change, resurgence. Concerns about the safety and reliability of market-distributed products. How to prevent recalls?

Unstoppable battery fires. Chaos from semiconductor supply shortages. How can we identify poor-quality products and prevent recalls? Poor-quality products are not limited to batteries frequently covered by the media, but also include OEM products, semiconductors that are in short supply, and a wide range of connectors and cables that users prioritize for appearance and price. Suppliers of products need to thoroughly evaluate the components and materials used in their products to ensure quality. However, it is common for manufacturers to change parts and usage without notice, leading to defective products entering the market unnoticed, which can trigger product accidents. Key points to prevent recalls include: - Product evaluation and safety assessment at the time of adoption - Confirmation of supplier quality assurance systems at the time of adoption - Verification of sales through legitimate domestic channels - Regular checks for silent changes Eurofins FQL has been involved in product quality assurance for a long time. Leveraging that expertise, we offer services for safety evaluations of batteries, identification of poor-quality products, and factory audits from the perspective of managing upstream quality.

-

USB-C and USB-PD, which have achieved high-speed data transfer and universal power supply, are essential items in daily life. Is the reliability assessment and quality check sufficient?

The European Union (EU) is implementing new regulations on December 28, 2024, to standardize the charging ports of electronic devices to USB Type-C. This USB Type-C offers many advantages, such as fast transfer speeds, a reversible design that enhances user convenience, and high-output power delivery capabilities, making it a powerful and speedy charging cable. The structure of the USB-C connector features 24 pins densely arranged in relation to the limited surface area of the power supply side, and USB-PD compatible with USB Type-C can support power delivery of up to 100W with a single cable. As a necessity, the risk of accidents in the market increases. - The connection can loosen due to insertion and removal, making it prone to short circuits when inserted at an angle. - Foreign substances can adhere, leading to tracking phenomena. - Usage in environments containing sweat, saltwater, and salt. Eurofins FQL offers product quality evaluations, long-term reliability assessments according to standards, and failure analysis. We also conduct evaluation tests focusing on environmental resistance (temperature and humidity, gas, saltwater), mechanical performance, physical performance, and electrical performance. We are here to help ensure thorough evaluation of products to prevent accidents before they occur. Please feel free to consult with us.

-

![[Free Seminar] Learning from Market Failure Cases of Poko Pin Connectors: Measures and Evaluation Methods for Shortened Lifespan](https://image.mono.ipros.com/public/company/logo/f39/401860/IPROS1517858276223614724.png?w=280&h=280)

[Free Seminar] Learning from Market Failure Cases of Poko Pin Connectors: Countermeasures and Evaluation Methods for Short Lifespan

Pogo pin connectors are essential components in today's technology industry, achieving excellent durability and stable electrical contact. However, this does not mean that market failures do not occur. To use them correctly and maximize their functionality, meticulous planning and precise engineering are required. They are widely used across various industries, including home appliances, automotive systems, medical devices, and aerospace technology, and further demand expansion is expected in the future. Therefore, learning from failure cases and implementing proper measures during the evaluation and design stages contributes to ensuring the reliability of the equipment. In this webinar, we will provide an excerpt from the "Failure Analysis Cases of Pogo Pins" presented by our company, Eurofins FQL, at the Reliability, Maintainability, and Safety Symposium hosted by the Japan Science and Technology Agency on July 17, 2025, due to its popularity.

Recommended products

Distributors

Eurofins FQL Co., Ltd. has its origins in the analysis division of Fujitsu Laboratories Ltd. and the quality assurance department of Fujitsu Ltd. It has long engaged in activities aimed at improving product quality, not only in material analysis, reliability evaluation, safety assessment, and failure analysis, but also in supplier quality management and manufacturing plant audits. Additionally, it contributes to solving challenges faced by organizations responsible for quality through the development and educational support of personnel involved in quality, as well as the construction and improvement of quality management, product chemical substance management systems, and software development processes. ■ Reliability Evaluation and Environmental Testing Various reliability evaluations, safety verification of secondary batteries and power supplies, etc., including smoke and fire hazards. Evaluation of special environments such as weather resistance and gas corrosion. ■ Failure Analysis Failure analysis of electronic components and devices, confirmation of characteristics related to materials, and detailed analysis of defects. ■ Support for Building and Improving Quality-Related Systems and Processes To achieve QCD (Quality, Cost, Delivery) goals, we support the improvement of development processes using models such as CMMI and Automotive SPICE. ■ Quality-Related Education Customized educational programs tailored to specific challenges, such as "I want to revitalize the organization," "I want to cultivate a quality mindset," and "I want to provide quality education for new employees."