Supplier Audit - Audit Agency and Quality Improvement Support Services

Are there any issues such as a high number of manufacturing defects or quality complaints from customers? We conduct quality audits of suppliers and manufacturing contractors on behalf of our clients.

On behalf of our clients, we conduct quality audits of parts suppliers and manufacturing contractors. We offer outsourcing of audits tailored to our clients' needs, which includes not only document-related checks and manufacturing process verification but also improvement advice for issues and confirmation of the implementation status of improvement measures.

basic information

■Extraction of Issues During the meeting, we will extract the customer's concerns and determine the confirmation process, scope, and check contents. ■Self-Check We provide a self-check sheet for the customer and business partners to conduct a preliminary review. ■On-Site Confirmation Based on the responses to the self-check sheet, we will conduct on-site confirmations at manufacturing plants, etc. ■Extraction of Issues and Cause Analysis We will identify issues such as lack of rules and deviations, analyze their causes, and provide advice on improvement measures. ■Follow-Up on Issue Improvement and Effect Confirmation We will conduct another on-site confirmation and report the results regarding the establishment and effectiveness of the improvement measures.

Price information

For more details, please contact us.

Delivery Time

Applications/Examples of results

We will assist you in solving your issues. - There are many manufacturing defects, and there are quality complaints from customers. - The manufacturing quality of Chinese products is unstable. - Quality complaints are not decreasing, and the costs for sorting inspections are increasing. - We do not know what kind of improvement guidance to provide to the factory. - We want to appeal the audit results from a third-party organization to our business partners.

catalog(4)

Download All CatalogsNews about this product(1)

Recommended products

Distributors

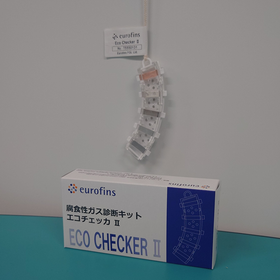

Eurofins FQL Co., Ltd. has its origins in the analysis division of Fujitsu Laboratories Ltd. and the quality assurance department of Fujitsu Ltd. It has long engaged in activities aimed at improving product quality, not only in material analysis, reliability evaluation, safety assessment, and failure analysis, but also in supplier quality management and manufacturing plant audits. Additionally, it contributes to solving challenges faced by organizations responsible for quality through the development and educational support of personnel involved in quality, as well as the construction and improvement of quality management, product chemical substance management systems, and software development processes. ■ Reliability Evaluation and Environmental Testing Various reliability evaluations, safety verification of secondary batteries and power supplies, etc., including smoke and fire hazards. Evaluation of special environments such as weather resistance and gas corrosion. ■ Failure Analysis Failure analysis of electronic components and devices, confirmation of characteristics related to materials, and detailed analysis of defects. ■ Support for Building and Improving Quality-Related Systems and Processes To achieve QCD (Quality, Cost, Delivery) goals, we support the improvement of development processes using models such as CMMI and Automotive SPICE. ■ Quality-Related Education Customized educational programs tailored to specific challenges, such as "I want to revitalize the organization," "I want to cultivate a quality mindset," and "I want to provide quality education for new employees."