SSD | Supports model selection, reliability evaluation, and failure analysis.

We will support you with issues such as model selection, reliability evaluation, and failure analysis.

In recent years, the transition from HDDs to SSDs has rapidly progressed in terms of performance, reliability, convenience, and price reduction. Additionally, to achieve faster, more efficient, and highly reliable data processing, the storage interface has become dominated by NVMe (PCIe). Our company possesses dedicated testers for mainstream NVMe (PCIe) SSDs (compatible with Gen3/Gen4) as well as testing environments for SATA/SAS. Leveraging our experience in handling SSDs for various applications, including laptops, desktop PCs, workstations, mission-critical servers, and storage, we contribute to ensuring the reliability of customer systems.

basic information

Reliability Evaluation - Environmental Testing (Temperature Cycle Testing: Confirming delamination or cracks at BGA joints within the SSD) - Power On/Off Testing (Confirming SSD failure to boot under arbitrary power On/Off spans and Write/Read combinations) - Long-term Running Test (Confirming performance degradation and stability of the SSD due to prolonged continuous operation) - Endurance Testing (TBW confirmation test) - Data Retention Testing (Confirming data retention characteristics of NAND flash memory within the SSD) - Performance Evaluation (Comparing/confirming performance of multiple manufacturers; details will be adjusted in consultation) Customizable according to customer requirements, such as aligning with the operating specifications of the planned system. Failure Analysis - Failure condition confirmation (SMART, error logs, appearance) - Write/Read error log analysis and reproducibility confirmation - Internal observation using X-ray Others

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(4)

Download All CatalogsRecommended products

Distributors

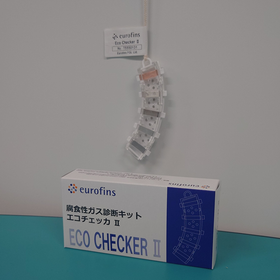

Eurofins FQL Co., Ltd. has its origins in the analysis division of Fujitsu Laboratories Ltd. and the quality assurance department of Fujitsu Ltd. It has long engaged in activities aimed at improving product quality, not only in material analysis, reliability evaluation, safety assessment, and failure analysis, but also in supplier quality management and manufacturing plant audits. Additionally, it contributes to solving challenges faced by organizations responsible for quality through the development and educational support of personnel involved in quality, as well as the construction and improvement of quality management, product chemical substance management systems, and software development processes. ■ Reliability Evaluation and Environmental Testing Various reliability evaluations, safety verification of secondary batteries and power supplies, etc., including smoke and fire hazards. Evaluation of special environments such as weather resistance and gas corrosion. ■ Failure Analysis Failure analysis of electronic components and devices, confirmation of characteristics related to materials, and detailed analysis of defects. ■ Support for Building and Improving Quality-Related Systems and Processes To achieve QCD (Quality, Cost, Delivery) goals, we support the improvement of development processes using models such as CMMI and Automotive SPICE. ■ Quality-Related Education Customized educational programs tailored to specific challenges, such as "I want to revitalize the organization," "I want to cultivate a quality mindset," and "I want to provide quality education for new employees."